Microfluidic laboratory

The microfluidics laboratory of SOLEIL is dedicated to the fabrication and analysis of microfluidic systems that are compatible with beamline applications. It benefits to a wide range of scientific domains, from solid-liquid interfaces to chemical reactions, single cell studies or protein crystallography. The availability of a microfluidic lab in SOLEIL is an opportunity that enables designing and preparing microfluidic systems adapted to the beamlines that would like to perform this type of in situ analyses.

The laboratory is equipped with state-of-the-art fabrication and analysis tools, in a dedicated clean room. The laboratory is accessible to all members of SOLEIL, as well as to external members that have a running project at SOLEIL or are planning to. The day-to-day organization of the lab and instruments maintenance is carried out by the members of the lab, but each user is responsible for realizing its own devices according to its project. Acces to the lab is granted after defining the proect with the lab manager and training on each instrument.

More details about the laboratory, its instruments and current projects can be found throughout this webpage. If you need more information than what you can find here, please do not hesitate to contact us.

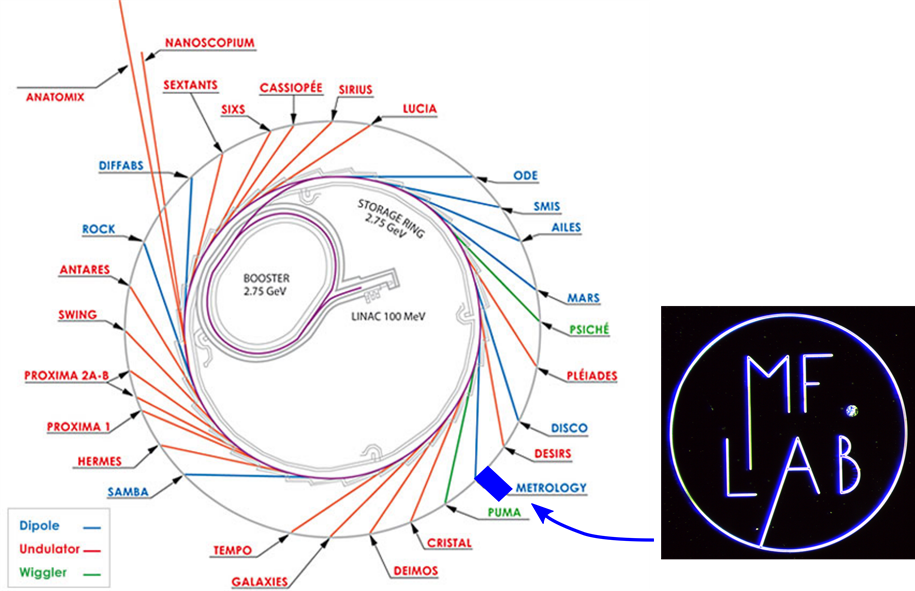

Where to find the lab?

The lab is located within the hall of the SOLEIL Synchrotron, right in front of the METROLOGIE beamline:

In-house users

DISCO : M. Réfrégiers, f. Jamme, V. Rouam

LUCIA: D. Vantelon, A. Beauvois

PX1/2 : L. Chavas, B. Sheppard, P. Montaville, R. Vasireddi, I. Chaussavoine

SMIS : F. Borondics, S. Lefrançois, C. Sandt

SWING : T. Bizien, J. Perez

External users

CEA - LIONS : F. Malloggi

Ecole Polytechnique - laboratoire de Biochimie: Yves Mechulam, Emmanuelle Schmidt, Pierre-Damien Coureux,Thomas Simonson, Alexey Aleksandrov

Team

* External service provider, temporary or collaborator

Curricula

• Dr. Benedikt Lassalle

Benedikt was trained as a chemist at the Universités de Strasbourg and Université d'Aix-Marseille, France. He obtained his PhD in inorganic chemistry in 2008 at the Insitut de Chimie Moléculaire et des matériaux d'Orsay, under the guidance of Dr. Elodie Anxolabéhère-Mallart and Pr. Ally Aukauloo. His thesis was focused on the synthesis and characterization of biomimetic highly-valent manganese complexes, as intermediate models for the water oxidation reaction in Photosystem II (PS II). He then spent a year as a post-doc at the Commissariat à l'Energie Atomique in Saclay, where he worked on the electrochemistry of PS II in the team of Dr. A. Bill Rutherford. In 2009, He moved on to the Lawrence Berkeley National Laboratory in the team of Vittal Yachandra and Junko Yano, where he spent three years as a post-doc. He worked both on the study of PS II and related model complexes using X-ray spectroscopy at synchrotrons and free electron lasers and on the in situ/operando study of electrocatalysts for water splitting. In 2014, he became a beamline scientist on the LUCIA beamline at SOLEIL, where he is pursuing his work on the operando study of electrocatalysts in collaboration with several teams in France and throughout the world. Since 2015, he has been appointed at the head of the microfluidics Laboratory of SOLEIL, where he is combining microfluidic techniques with spectroscopy and energy-related electrocatalysis.

• Dr. Ramakrishna Vasireddi

Dr. Ramakrishna Vasireddi is a Postdoctoral Research Scientist at Synchrotron SOLEIL, PROXMIA-1 beamline, Paris, France. He received his Doctorate in Physics in the arena of Microfluidics and X-Ray Scattering from the Hamburg Centre for Ultrafast Imaging (CUI), Department of Physics, University of Hamburg at Deutsches Elektronen-Synchrotron (DESY), Germany.

His research involves making molecular movies of structural matters with atomic resolution and at ultrashort time scales. He works on the cutting-edge microfluidic techniques to combine ultrabright X-rays (Synchrotrons) for understanding these fast dynamic processes in action.

His current research is focused on the investigation of structure-function relationship and dynamics of biological macromolecular crystals using X-rays at extremely low sample volumes. Early 2019, he joined the microfluidic lab in the framework of the AAPG ANR project Carb2zyme. He is currently working on development of X-Ray compatible microfluidic devices for biomacromolecular structural studies (serial crystallography) at PROXIMA beamline.

• Mr. Stéphane Lefrançois

After spending more than ten years at the national metrology office (BNM), Stéphane joined the SMIS beamline as an assistant engineer. For more than fifteen years, he has been developping Infra-Red optical systems for the SMIS beamline at SOLEIL as well as for other synchrotrons (ALBA and SESAME). He also developped microfluidic systems for biological IR imaging under physiological conditions for the MSIS beamline and for INRA laboratories. In 2017, Stéphane was promoted as an engineer and joined the microfluidic lab for part of his time, while continuing his work at the SMIS beamline.

Access to the lab

Access to the lab is reserved to SOLEIL members or users with a proposal accepted through SOLEIL's review panels (SunSet). External users interested in using the microfluidic lab should either contact the lab's responsible directly or a beamline scientist that is familiar with the lab. A short written notice describing the goals of the project and the instruments and ressources of the lab required might be asked for.

The fabrication of microfluidic devices, including their design and the choice of materials, is the responsibility of users, but the microfluidic team will be happy to orient and help to the best of its capabilities. Common and microfabrication-specific chemicals and consumables are available in the lab, but specific needs should be discussed and planned in advance.

The everyday maintenance tasks of the lab are performed by the lab's assistant, but each user is responsible for taking care of its own experiments and maintaning the lab in a decent situation.

Instruments

Fabrication

• Laserwriter (KLOE-Dilase 250): A high resolution (4µm) direct laser (375 nm) lithography system for versatile prototyping and maskless fabrication.

• Plasma cleaner (Henniker HPT-100): O2, Ar, N2 and air plasma cleaner.

• Insulating device (KLOE UV-KUB 2): UV light insulating device to be used with a mask.

• Spincoater (Laurell WS-650-23NPP): rotation speed, time and accelaration is programmable.

• Electronic cutting printer (Silhouette Cameo): This device allows cutting microfluidic spacers from thin sheets of plastic.

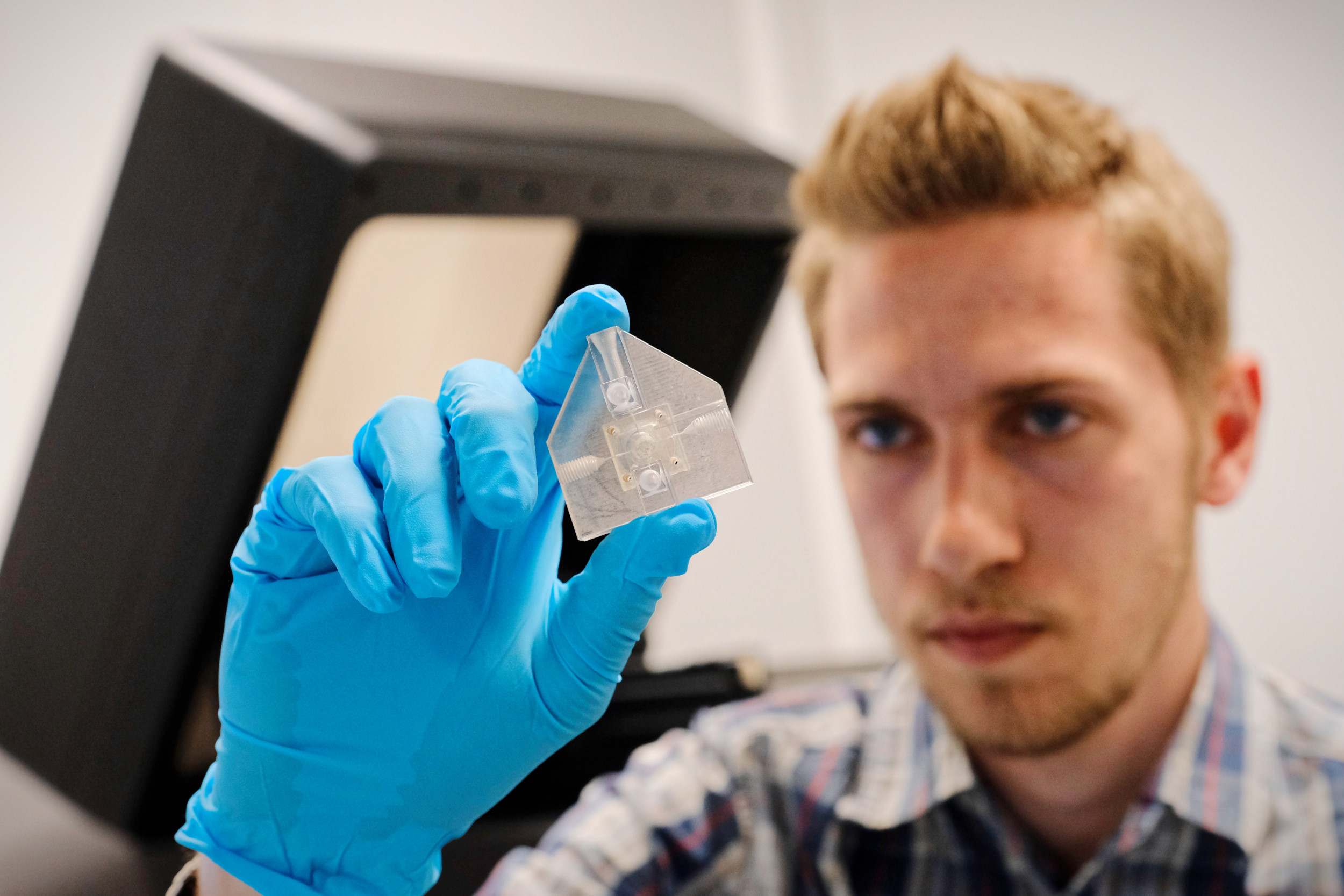

• 3D Printer (Objet30 Pro, Stratasys): Precision Desktop 3D Printing with PolyJet technology. Verowhite and Veroclear materials are available, with single layer thicknesses of 32 and 16 µm, respectively.

• Hotplates, chemical bench, sonicator, distilled water.

• Fume hood and laminar flow cabinet.

Analyse

• Profilometer (gbs smart WLI): fast, non-contact 3D imaging system with micrometer resolution.

• Macroscope (Leica DMS 1000).

• Custom-made microscope 10x & 50x (equipped with a camera)

• pressure and flow controller (ELVESYS OB1 MK3): 3 independent channels (1 x 0-200 mbars, 2 x 0-2 bars) and flow sensors.

• Syringe and peristaltic pumps.

In House projects

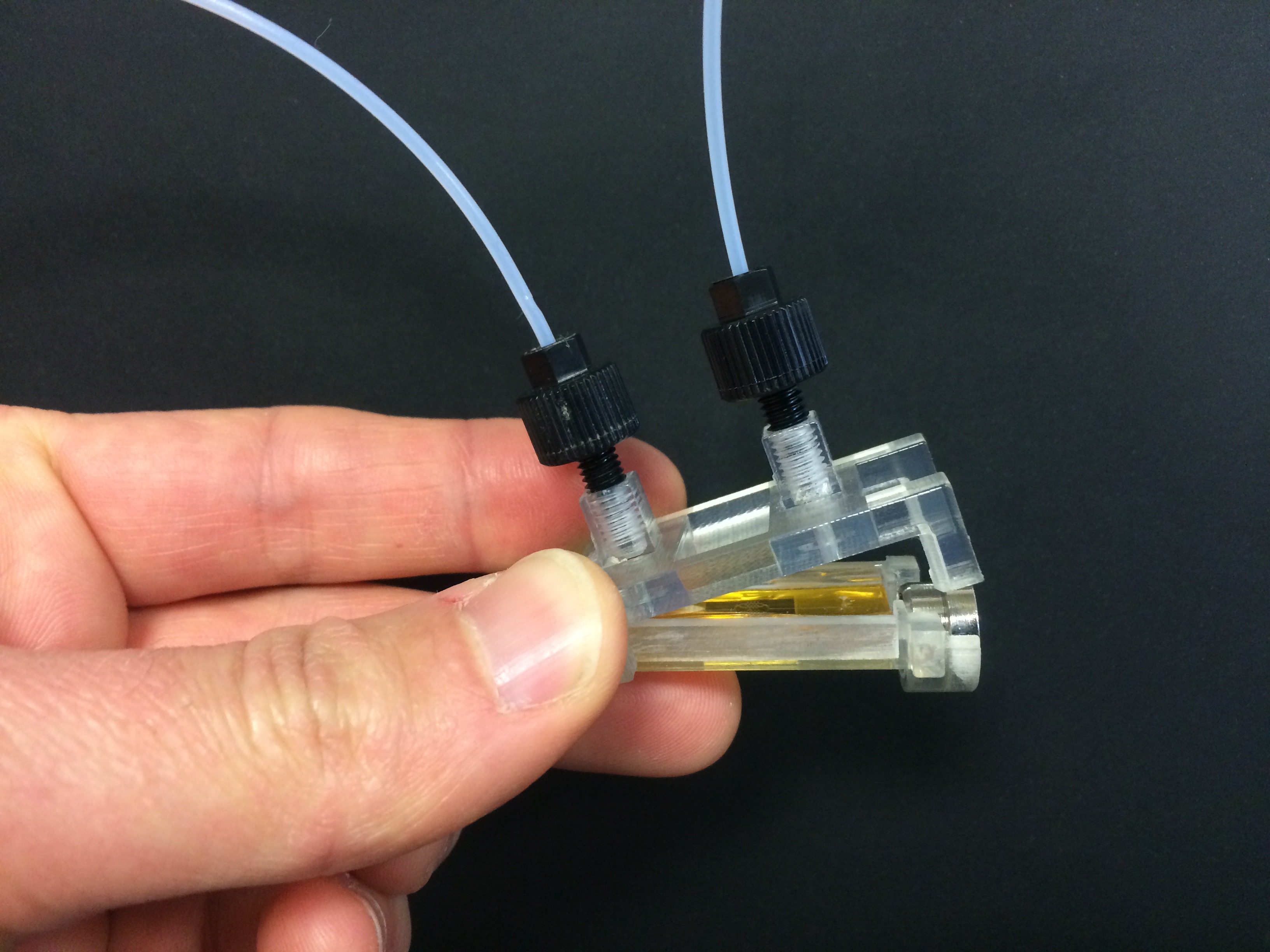

• Trap-chips:

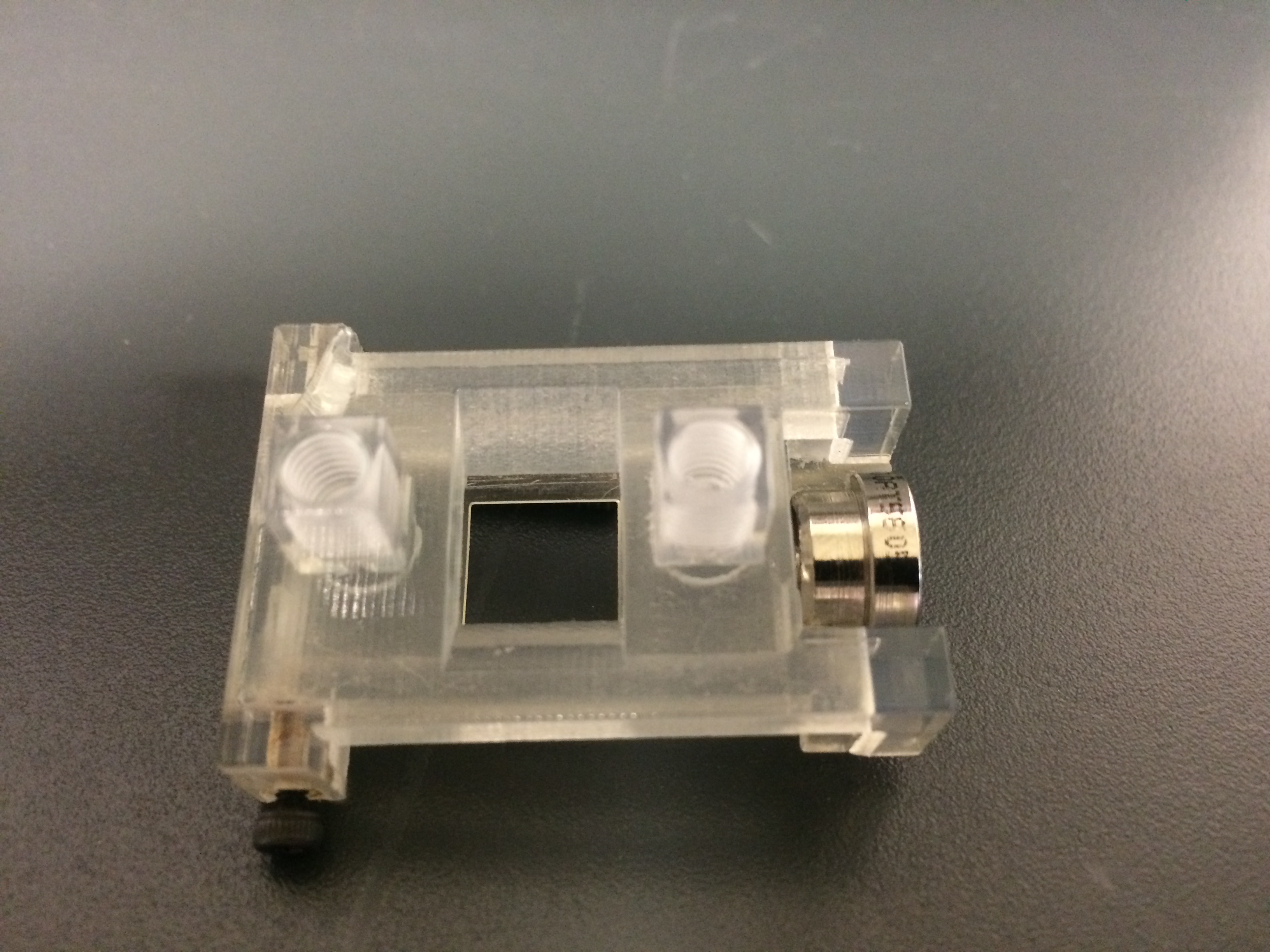

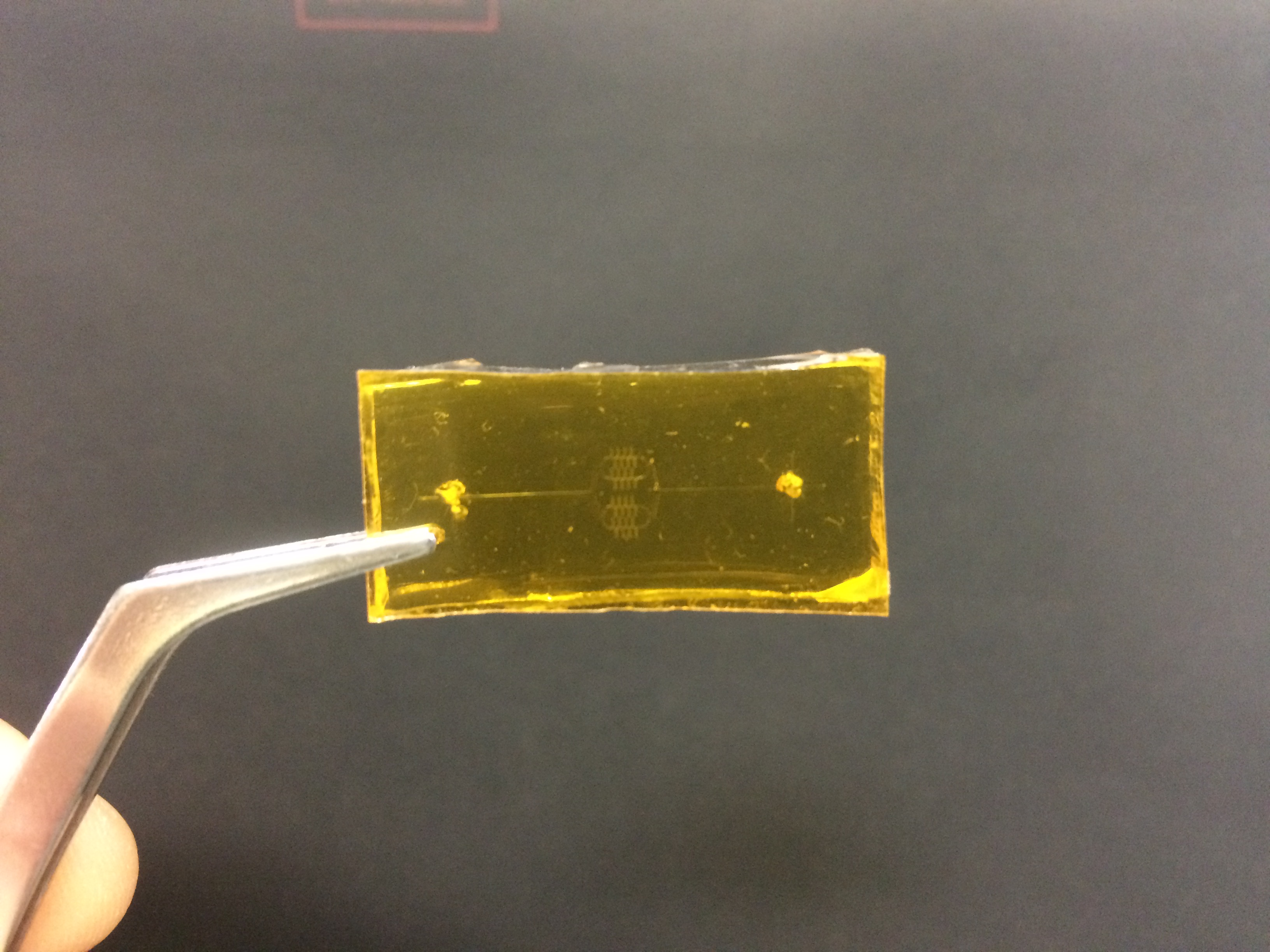

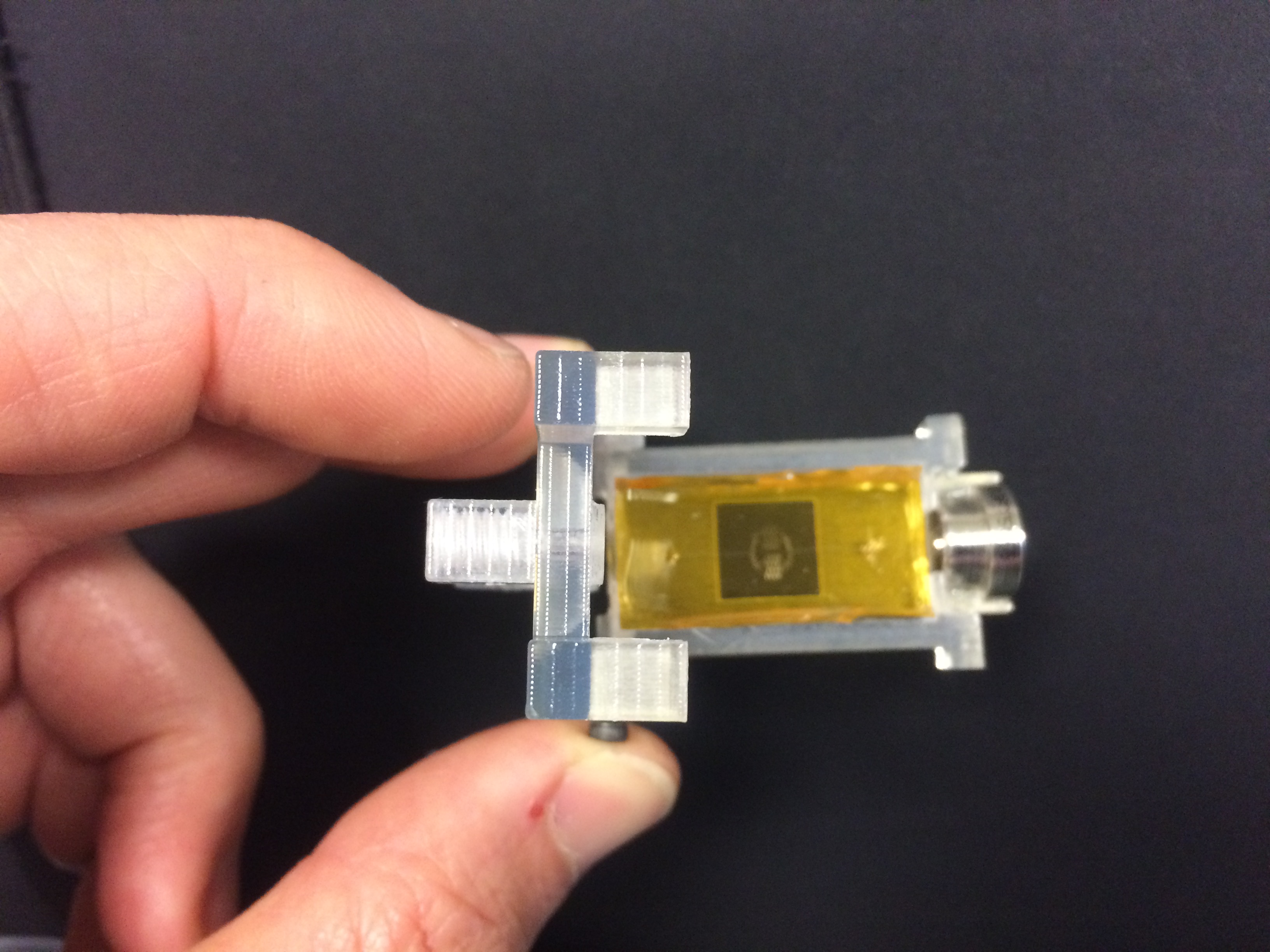

This project, carried out in common with the Proxima-1 team, aims at preparing micro-traps that can immobilize micro-crystals and position them precisely in an X-ray beam to collect diffraction data. This allows measuring data under physiological conditions and at room temperature. Sorting crystals or even cells for further in line anlysis is also a part f this project. Igor Chaussavoine, PhD candidate on PX1, Pierre Montaville, post-doc on PX1 and Leonard Chavas, beamline manager on PX1 are all involved in this project. A few pictures below show the chips made and the support used to position them on the PX-1 goniometer.

In situ crystallography trap-chip. Top to bottom: goniometer-compatible holder for a trap-chip, trap-chip, trap-chip in the open holder and in it's holder ready to be loaded.

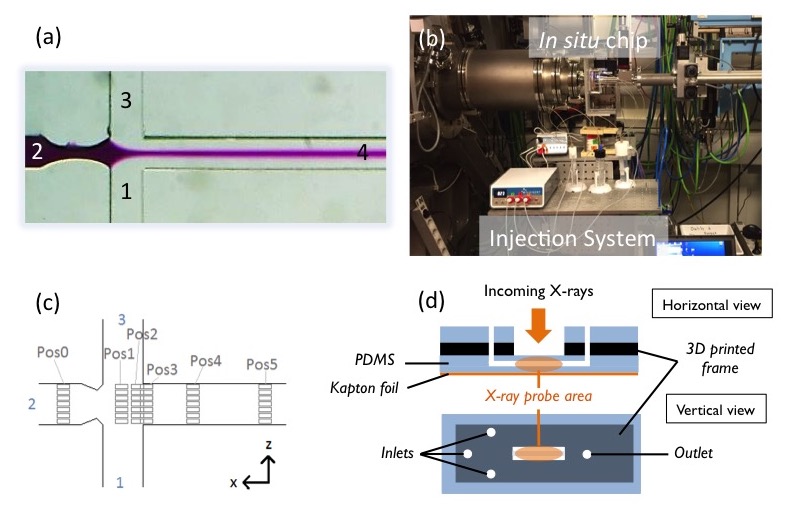

• TR-WAXS:

The SWING beamline is carrying out a project to develop in-line microfluidic mixers, which allow following chemical or biochemical reactions with WAXS. The dynamics of nanoparticles formation or protein folding reactions can all be tracked using this method. This project is carried out by Thomas Bizien, beamline scientist on SWING.

Time-resolved SAXS/WAXS in situ experiments. (a) flow-focusing mixing channels, (b) in situ setup installed on the SWING beamline, (c) data collection positions corresponding to the mixing channels in (a) and (d), schematic representation of the microfluidic mixing device structure.

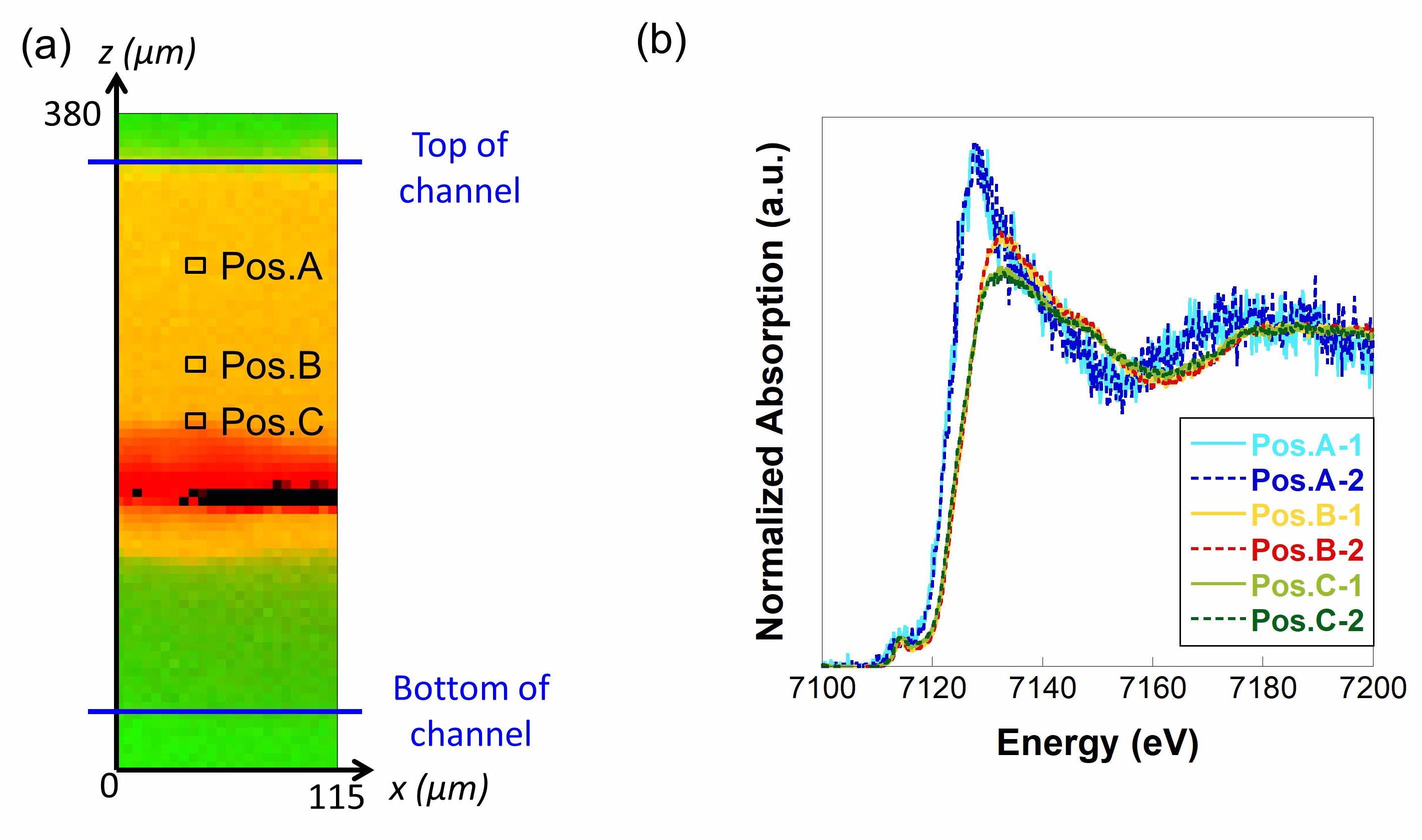

• In situ µ-XRF et µXAS:

We have developped a mixing microfluidic chip that is compatible with primary (10-2 mbars) vacuum. This cell allows using the micro-focused (3x3µm) of the LUCIA beamline to observe the formation of nanoparticles in situ by µ-XRF and µ-XAS. This project is carried our by Delphine Vantleon and Anthony Beauvois on the LUCIA beamline.

In situ µ-XRF and µ-XAS: (a) K-edge Fe fluorescence map of the channel (the iron concentration increases on goinf from green to orange and to red, black indicating the saturation of the detector). The lower part of the canal contains NaOH while the top one contains FeCl2. At the interface, FeOx nanoparticles are formed et precipitate. (b) Fe K-edge XANES spectra recorded on points A, B et C. Two consecutive sepctra were recorded at each point, thus demonstrating the absence of beam-induced damages.

• Sequential CO2 reduction:

This project aims at developping micro-reactors that can host electro-or photo-chemical reaction, which are arranged in series to form a sequential chemical synthesis system. We are particularly interested in the sequential reduction of carbon dioxide (CO2) into light hydrocarbons or basic chemical building blocks.

External collaborations

• CEA LIONS:

We have an active collaboration with Drs. Florent Malloggi, Corinne Chevallard and Patrick Guenoun to develop microfluidic cells adapted to IR and X-ray spectroscopies.

• Ecole Polytechnique, Biochemistry Laboratory:

We are collaborating with the team of Drs. Yves Méchulam and Thomas Simonson for the development of microfluidic mixers that can trap conformational intermediates in the protein folding reactions.

Latest news

• 21/09/2020: Zoé Joined the team as an apprentice for the next two years. In parallel to her Masters in material chemistry and science at the Université d'Evry, she will work on the time-resolved sample preparation system for electron microscopy. Welcome Zoé!

• 11/09/2020: Yuan-Yuan was awarded the best poster price at the Lab-on-a-chip and Microfluidics conference in Rotterdam. Her low flow rate fast mixer is getting noticed. Congratulations!

* * * 2019 * * *

• 07/11/2019: The first paper of the microfluidic lab has been accepted! It will be published in the Journal of Synchrotron Radiation (currently in press) and will describe the facilites of the lab, as well as proof-of-concept projects on microfluidic devices for in situ µ-XRF and µXAS, SAXS/WAXS or single crystal X-ray diffraction experiments. Congratulations to all co-authors!

• 14/10/2019: Si-Thanh Dong is joining the lab as a PhD student. He will work on the MF-CO2 ANR project for the sequential reduction of CO2 under microfluidic conditions. Welcome Thanh!

• 30/07/2019: The Serial-X-Energy ANR proposal has been accepted! It is a collaboration betweenSOLEIL, the Institut Lavoisier in Versailles and the Ecole Normale Supérieure for the study of Polyoxometallates (POMs) iinserted in Metal Organic Frameworks (MOFs) by in situ serial X-ray diffraction. A post-doc offer will soon be published!

• 23/05/2019: Mathis Brossier, undergraduate student at Polytech Paris-Sud, joins the team for a 2-month internship. He will work on the control of a circular motor that allows freezing biological samples on the millisecond timescale.

• 18/02/2019: Thanh Dong Si, Master student in the Erasmus Mundus SERP-CHEM Master is joining the team. He will do his Master's thesis on the fabrication of microfluidic electrochemical devices for the sequential reduction of CO2. Welcome!

* * * 2018 * * *

• 10/09/2018: Benedikt was invited at a workshop on the machine upgrade at the Diamond Light Source, UK, to present the advances of the microfluidic lab. Microfluidics is becoming more and more popular within the synchrotron community!

• 12/07/2018: Benedikt has been awarded a young researcher grant from the ANR to work on the sequential reduction of CO2 using microfluidic reactors. A post-doc will be recruited on this topic in the spring of 2019, watch for the job advertisement!

• 15-16/03/2018: Igor and Benedikt presented posters at the annual meeting of the Groupe de Recherche on Micro/nanofluidics in Grenoble. Nanoscale fabrication techniques, acoustofluidics and micron-sized object manipulations were all there!

• 01/03/2018: Yuan-Yuan Liao just joined the lab as a post-doc, welcome! During her PhD, Yuan-yuan used microfluidics to study the precipitation of organic nanoparticles using FLIM spectroscopy. In the framework of the ANR project TREMTI, and in tight collaboration with the team of Dr. Yves Mechulam at the Ecole Polytechnique, Yuan-yuan will work on the fabrication of microfluidic mixers for the preparation of cryo-EM time resolved samples.

• 18/01/2018: The ivMX (in vivo Macromolecular Crystallography) satellite workshop of the SOLEIL User's Meeting was held in SOLEIL on January 16-17. Several members of the microfluidic lab attended and Igor Chaussavone gave a talk on his PhD work. Microfluidic tools are becoming instrumental in this nascent field: numerous developments in microfluidics are expected for diagnostic, selection, sorting and positioning of cells containing microcristals!

* * * 2017 * * *

• 01/11/2017: Stéphane Lefrançois is joining the team as an engineer, welcome to you! Stéphane has been and assistant engineer on the SMIS beamline for several years, where he developped IR optical systems as well as IR-compatible microfluidic devices. He has also design and setup several IR beamlines at other synchrotron light sources (ALBA, SESAME). He has just been promoted as an engineer and will share his time between the SMIS beamline and the microfluidics lab.

• 13/07/2017: The Microfluidic lab, together with the PX1 team and the Biochemistry Laboratory at Ecole Polytechnique has been awarded an ANR Grant to develop microfluidic mixers fro the study of transient biochemical processes. Watch for the post-doc job opening!

• 10/06/2017: Tiphaine defended her first year project and recieved 18.5/20. Congratulations!

• 03/04/2017: Baptiste Maurice joins the lab as an undergraduate intern. He will develop a flow cell adapted for Hard X-ray transmission and fluorescence measurements.

* * * 2016 * * *

• 19/12/2016: Upgrade du dilase250, amélioration du software et des performances du laserwriter. Nous avons fait des tests pour le comparer à son ancienne version : il y a beaucoup moins de problème pendant l'impression, et le logiciel qui pilote la machine est plus intuitif.

•05/10/2016: Tests en résolution sur l'imprimante 3D.

Petit canal (500µm) dans fine membrane :

• 05/09/2016: L'imprimante 3D vient d'être installée! Nous pouvons maintenant produire des systèmes sub-millifluidiques en un bloc, et la machine travaille pour nous!

• 01/09/2016: Bienvenue à Tiphaine MATEO qui nous rejoint pour les 3 prochaines années! Elle est apprentie-ingéneure à l'école Polytech Paris-Sud et aidera les utilisateurs à mettre en place leurs projets au sein du laboratoire. A part la microfluidique, Tiphaine aime l'escalade, le skate-board et les minéraux.

• 12/05/2016: Ecoulement laminaire de deux solutions colorées au sein d'un canal de 20µm de large d'une puce PDMS/verre.

• 15/01/2016: Première réalisation de lithographie avec le laserwriter!

job offers

We are currently hiring an M2 student with a background in chemistry or physical-chemistry for the development of a microfluidic platform for electrocatalysis. The project can be consulted here:

M2_microfluidic.

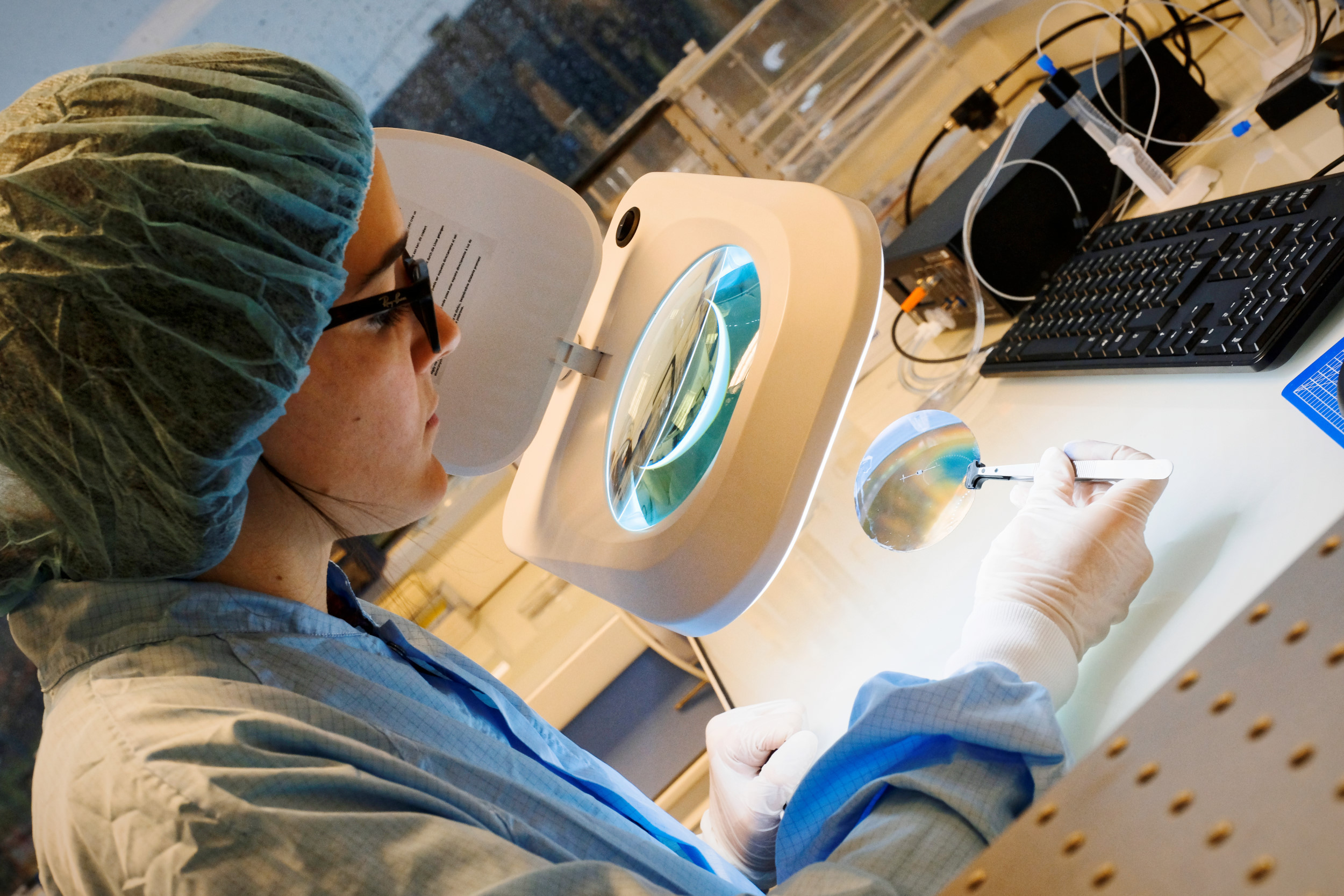

Lab members in June 2017.

From left to right: Baptiste Maurice, Tiphaine Mateo, Benedikt Lassalle.

Baptiste is cleaning wafer, Tiphaine is testing a chip and Benedikt checks the patterns of a mold using the profilometer.

Baptiste checks the channels of a freshly made 3D-printed cell.

Tiphaine checks a resin pattern on a wafer.

Benedikt uses the optical profilometer to measure the dimensions of a mold after the lithography process.

Rain may be falling, Tiphaine keeps focused on her channels.

Photos credits Vincent Montcorgé.