Hydrogenation of carbon dioxide to methane to reduce CO2 emissions

Coherent diffraction imaging enables the study of nanocatalysts for hydrogenation in action

On SOLEIL’s SIXS beamline, for the first time ever, researchers from Aix-Marseille University (IM2NP laboratory), SOLEIL, ESRF (Grenoble, France), Eindhoven University of Technology (TU/e, the Netherlands) and Technion – Israel Institute of Technology, carried out Bragg coherent X-ray diffraction imaging (BCDI) on platinum (Pt) and nickel (Ni) nanoparticles during their catalytic reaction: either during CO oxidation on Pt or CO2 on Ni.

The hydrogenation of CO2 into methane is considered a plausible process for storing renewable energy in the form of methane, reducing anthropogenic CO2 emissions and so reducing global warming. Ni is one of the most widely used catalysts in CO2 hydrogenation due to its high selectivity and low cost. However, Ni nanoparticles undergo structural changes during the catalytic reaction. In particular, poorly coordinated sites such as edges, as well as their implication on the catalytic properties of the reaction, are not fully understood. Understanding the role of elastic deformation is crucial in the design of catalytic converters, and should help to improve the understanding and location of their active sites and deactivation processes.

Bragg coherent X-ray diffraction imaging (BCDI) is a technique as yet not very widely applied to the determination of the structure of nanoparticles. It enables the three-dimensional (3D) probing of the structure (atomic displacement field, deformation field, defects, morphology, size, composition...) of nanoparticles (size between 100 nm and 1 µm) with a spatial resolution of approximately ten nanometers and a sensitivity to fluctuations in the displacement field in the picometer range.

This technique, developed in the early 2000s, requires an intense X-ray source obtained, for example, by focusing the X-ray radiation from the undulator of a 3rd generation synchrotron, such as the SOLEIL SIXS beamline. Using the CRISTAL beamline focusing system (Fresnel lens) installed on SIXS, the researchers were able to focus the beam to approximately 1µm (vertically) and 2 µm (horizontally) and measure Pt and Ni nanoparticles of around 500x500x300 nm3 during their reaction in the SIXS catalytic reactor.

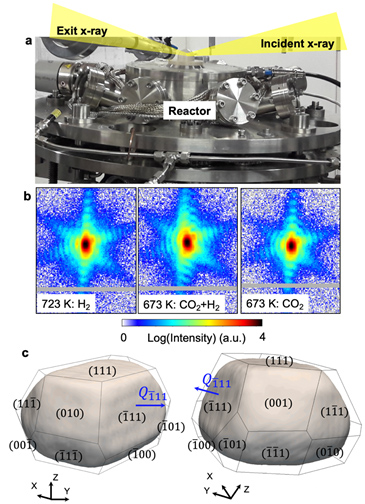

The experimental device is presented in Figure 1a.

For this, the researchers mapped the intensity diffracted by a nanoparticle around a diffraction peak (also called a Bragg peak) in 3D (Figure 1b) and used a phase retrieval algorithm to finally obtain a complex 3D image of the measured object. The image module (Figure 1c) is proportional to the electronic density of the object and its phase is proportional to its atomic displacement field. It should be noted that the researchers could analyse all the 3D diffraction images during the experiment and reconstruct the nanoparticles at the different stages of the reaction (i.e., at various temperatures and gaseous environments) thanks to the availability of a central unit with graphics card during the experiment.

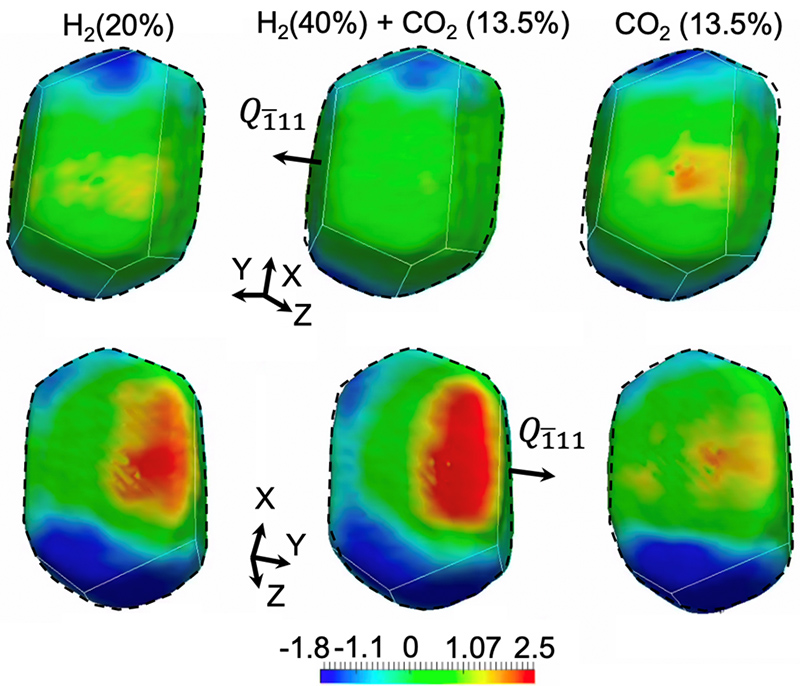

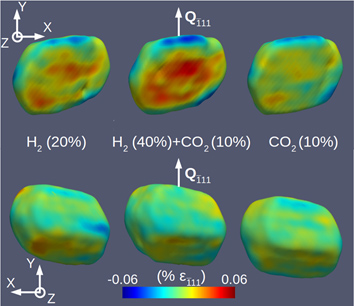

The researchers demonstrated that it is possible to access the displacement field (proportional to the phase - see Figure 2) of catalytic particles during their reaction. They could demonstrate the reproducibility of the evolution of the displacement field during various gas cycles. To obtain a more accurate idea of the evolution of the deformation during the reaction, it is possible to deviate the deformation field from the displacement field (Figure 3). This study should lead to a better understanding of the correlation between structural and catalytic properties during the reaction.

The team made a breakthrough on SIXS by exploiting the beam coherence of the X-ray beamline, by focusing this beam to a couple of microns and by demonstrating the potential to conduct in situ and operando measurements using coherent X-ray diffraction (the reactor is connected to a mass spectrometer) on nanoparticles during a chemical reaction. This technique paves the way to the 3D analysis of the internal structure of nanoparticles and their optimization during catalytic reactions. With this technique, the structural evolution of nanoparticles can be characterized not only during chemical reactions, but also to various strain-related phenomena, during their growth, etc.

This technique will benefit from the SOLEIL synchrotron upgrade in terms of flow and coherence, and in the future is expected to become a remarkable technique in the structural characterization of nanoparticles.