Researchers from the Centre des Matériaux – Mines Paris (PSL) have achieved a world-first at the SOLEIL synchrotron: real-time 3D X-ray imaging of steel deformation and fracture under pressurized hydrogen gas. The objective is clear: to understand how hydrogen embrittles steels used in transport infrastructures, a fundamental challenge to ensure the safety of future hydrogen networks.

Using the PSICHE beamline and a custom-built hydrogen tensile pressure machine, designed and manufactured with the French SME Top Industrie, the team visualized and quantified in situ how damage evolves in the presence of hydrogen. First results, presented at EUROMAT 2025, reveal the influence of delta ferrite on hydrogen embrittlement of a 316L stainless steel.

Hydrogen, a challenge for materials

Hydrogen is a key enabler for the energy transition, particularly in transport and storage applications. However, its interaction with steels often leads to hydrogen embrittlement, a critical issue that reduces ductility and toughness and can compromise the safety of infrastructures. Until now, most studies relied on post-mortem analysis or indirect measurements, with little direct evidence of how damage initiates and propagates in steels exposed to gaseous hydrogen.

Breakthrough results

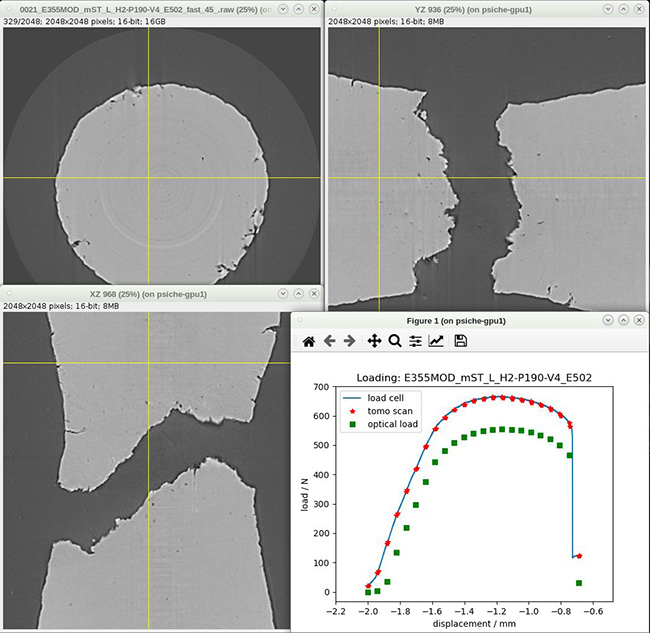

In July 2024, a pioneering experiment was conducted on the PSICHE beamline at SOLEIL. For the first time worldwide, researchers achieved in situ 3D X-ray tomography of a metal deforming under high-pressure hydrogen gas. These results were obtained in the context of a joint PSICHE / Centre des Matériaux (CMAT) post-doctorate, illustrating the close collaboration between the two institutions.They were made possible by a custom-built hydrogen tensile pressure machine, designed and manufactured in partnership with the French SME Top Industrie. The rig integrates a miniature high-pressure chamber coupled with a tensile stage, allowing synchrotron tomography scans at micron resolution (voxel size ~0.65 µm) during deformation under hydrogen gas pressures up to 200 bars.

This unique setup enabled researchers to visualize and quantify damage evolution in real time, revealing how hydrogen alters fracture mechanisms compared to tests in air. Instead of uniform plastic damage, hydrogen promotes localized cracking and accelerated microcrack growth. First results presented at EUROMAT 2025 demonstrated the role of delta ferrite in controlling hydrogen embrittlement in 316L stainless steel, with cracks preferentially nucleating and propagating along ferrite bands.

Figure 1: In situ X-ray tomography of a ferritic steel miniature specimen tested under 190 bars of hydrogen gas at the PSICHE beamline. Damage can be visualized in 3D during loading, enabling direct observation of hydrogen-induced fracture mechanisms.

Contribution of SOLEIL

The success of this first experiment relied on the PSICHE beamline’s ability to deliver high-energy, high-flux X-rays with rapid scan times, combined with the flexibility to host complex custom-built rigs. A crucial aspect was safety: the tensile pressure machine, developed with Top Industrie, integrates a miniature high-pressure chamber with a very small hydrogen volume, making the tests intrinsically safer. This design enabled the proof-of-concept experiment to be carried out under non-ATEX conditions, in close collaboration with SOLEIL’s safety services. Without this synergy between advanced beamline capabilities and stringent safety engineering, such world-first 3D imaging of steels under hydrogen gas would not have been possible.

Figure 2: Control room at the PSICHE beamline during the world-first hydrogen–tomography experiments. Close collaboration between researchers, engineers, and SOLEIL safety services ensured the safe operation of the custom-built tensile rig.

Next steps

This breakthrough marks the starting point of a series of experiments within the European HYWAY project (2024–2028), coordinated by Mines Paris – PSL. Future work will expand to other alloys, microstructures, and strain rates, to systematically unravel hydrogen–plasticity interactions. Ultimately, these studies aim to establish robust design criteria and testing protocols for hydrogen infrastructure materials.

Impact

By directly imaging hydrogen-induced damage in steels, this research opens unprecedented possibilities to connect microstructure, environment, and fracture mechanisms. It represents a decisive step toward safer steels for hydrogen pipelines, storage tanks, and critical energy infrastructures.

Figure 3: Real-time visualization of crack initiation and propagation in stainless steel 316L under hydrogen gas. Cracks nucleate at specimen edges and follow ferrite bands, demonstrating the role of microstructure in hydrogen embrittlement.