Unraveling the Mysteries of a novel TiS2 Ultrathin Film Synthesis Approach

In the ever-evolving landscape of materials science, the quest for innovative techniques to fabricate ultrathin films of transition metal dichalcogenides1 has taken a significant leap forward with a pioneering study focusing on titanium disulfide (TiS2). Harnessing the power of in situ X-ray absorption spectroscopy at SIRIUS beamline and DFT2 calculations, collaboration between the researchers of various institutes have delved deep into the intricate chemistry and structural dynamics underlying the growth of TiS2 films via in situ probing an ingenious two-step process

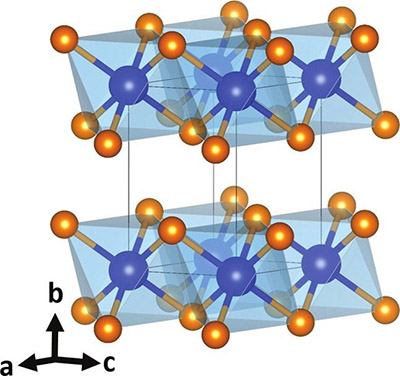

Transition metal dichalcogenides (TMDs), particularly lamellar TiS2, (see figure 1) have garnered considerable attention owing to their potential applications in diverse fields ranging from energy storage to electronics.

However, the fabrication of ultrathin TiS2 films suitable for large-scale production remains a formidable challenge. Traditional methods such as mechanical exfoliation lack the precision and scalability required for practical applications, prompting researchers to explore bottom-up growth techniques like atomic layer deposition, “ALD”. The conventional ALD process faces hurdles in achieving precise control over crystal structure due to the simultaneous occurrence of atomic growth and crystallization.

To overcome this limitation, the innovative atomic layer deposition/molecular layer deposition (ALD/MLD) approach offers a promising solution. In the framework of the ANR Project ULTIMED, by combining ALD for inorganic materials with MLD for organic thin films, researchers here from LMGP, CNRS and CEA-LETI in Grenoble, IRCELYON in Lyon, IPVF in Palaiseau and SIRIUS beamline at synchrotron SOLEIL, have devised a strategy to separate growth from crystallization, thereby enabling precise control over film thickness and structure.

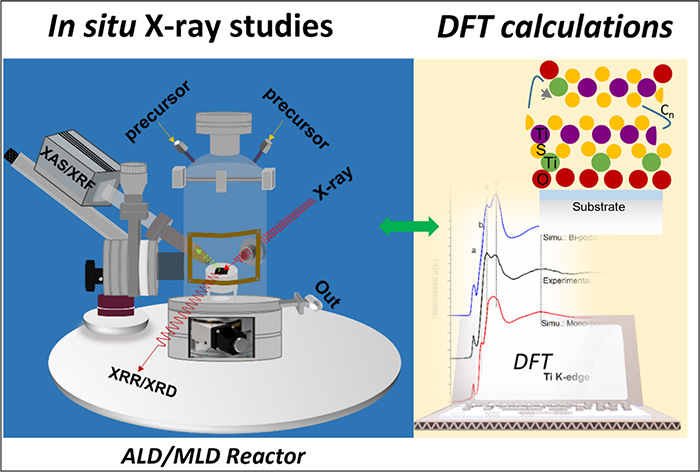

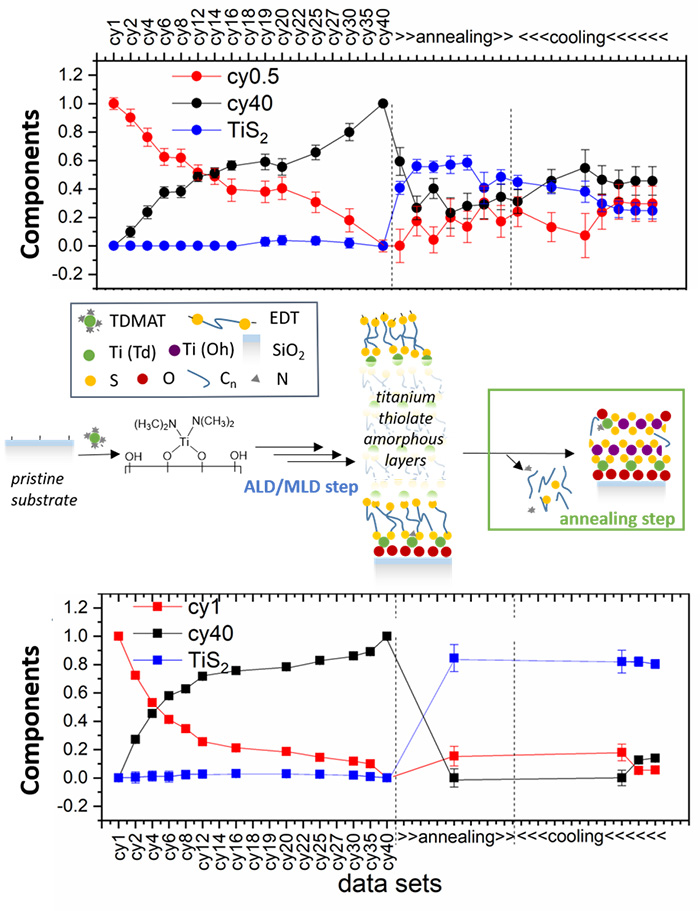

In this groundbreaking study, the team investigated the chemical and structural mechanisms governing each step of the TiS2 film growth process. Through comprehensive in situ x-ray absorption spectroscopy (XAS) analysis and density functional theory (DFT) simulations, they elucidated key aspects such as precursor-substrate interactions, formation of non-crystalline intermediate thiolates, and crystallization kinetics during annealing. Notably, the study unveiled the critical role of annealing in facilitating the transformation of amorphous Ti-thiolate into nanocrystalline TiS2, validating the efficacy of the two-step synthesis approach.

The experimental setup, housed at the SIRIUS beamline of synchrotron SOLEIL (figure 2), provided unprecedented insights into the evolution of TiS2 films in real-time via various simultaneous characterizations e.g. XAS, x-ray fluorescence (XRF), x-ray reflectivity (XRR) and Ellipsometry.

Based on the results from these techniques, a schematic overview of the entire ALD/MLD + annealing process has been developed (figure-3). By leveraging advanced XAS techniques and DFT modeling, the researchers gained a deeper understanding of the atomic-scale processes driving TiS2 film growth, paving the way for future advancements in the field of ultrathin layered materials.

In conclusion, this groundbreaking research not only sheds light on the intricate chemistry and structural dynamics of TiS2 film growth but also opens new avenues for the controlled synthesis of ultrathin TMD films with tailored properties. As the quest for next-generation materials continues, the synergistic combination of advanced characterization techniques and theoretical modeling holds immense promise for unlocking the full potential of nanomaterials in various applications.

-----------------------------------------------------------------------

1 - Transition-metal dichalcogenide (TMD or TMDC) monolayers are materials that exist in the form of layers consisting of only 3 planes of atoms, separated by a van der Waals gap which limits the interaction between the layers; we refer to 2D materials. Their physical properties are very anisotropic. They are of the type MX₂: M is a transition metal atom, X a chalcogen atom, the plane of atoms M is sandwiched between the two planes of atoms X.

2 – DFT is a computational quantum mechanical modelling method used to investigate the electronic structure atoms, molecules, and condensed matter.