A new microscope dedicated to the interferometric measurement of optics at SOLEIL

Characterization of the mirrors used on SOLEIL beamlines to focus the radiation to dimensions of a few hundred nanometers requires the development of measuring instruments that are not commercially available. The SOLEIL optics group has thus had to develop, in collaboration with the company EOTECH, a microscope specifically adapted to attain the level of precision required to characterize the optics at SOLEIL.

The resolution required to characterize these optics must be less than 1 nm and with a reproducibility of around 0.1 nm. Several instruments are needed to observe the optical components, each being effective for a specific spatial range. The metrology laboratory of the Optics Group has instruments for detecting defects of lateral dimension greater than 500 microns, using an optical profilometer and/or a Shack-Hartmann type wave front sensor. Yet, the need for better and better optics in terms of focusing quality has led to the observation of defects at much smaller dimensions, down to 50 microns. It was therefore necessary to design a microscope with greater magnification but maintaining a resolution of 1 nm. All these constraints led the Optics Group to the decision to develop a phase scanning interferometer, a principle already used by other synchrotron metrology laboratories, based on heavily modified versions of commercial instruments.

The result of collaborative work

To achieve such a performance, it was necessary to control all elements of the metrology system: optics, acquisition control and numerical calculations required to reconstruct the surface topography. In addition, it was also necessary to obtain an optical system the least sensitive possible to distortion and focusing defects. The development of a telecentric interferometric objective was therefore required suitable for the field of observation. Several manufacturers were contacted and only the company EOTECH accepted the challenge of helping the Optics Group to develop this instrument based on the concept of a telecentric lens proposed by the MBO metrology company.

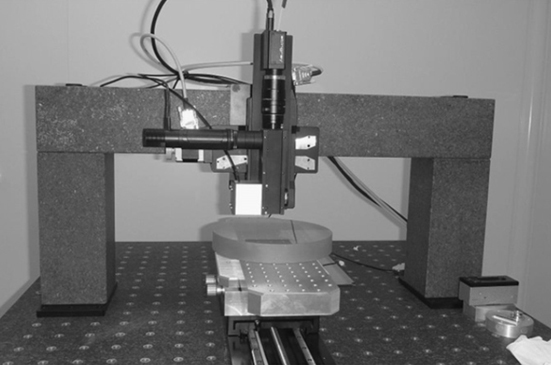

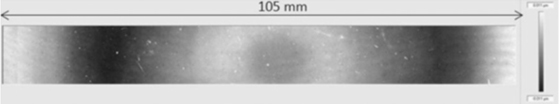

To begin with, a first prototype was developed during 2011 to validate the optical system and the acquisition chain. In the summer of 2012, a final version was installed in the metrology laboratory of the Optics Group, in a dedicated, temperature and humidity controlled, room (Figure 1). In order to be able to measure the total surface of the optic, this was mounted on a translation stage. The total topography of the mirror is reconstructed by successively connecting images taken on the mirror (Figure 2). A measurement repeatability greater than 0.2 nm was obtained during the measuring cycle.

Future measurement comparisons are planned with other metrology laboratories during 2013 in order to improve the analysis of the instrument’s resolution. As the instrument is completely flexible and changeable, its characteristics will evolve over time.

This work was funded by Région Ile de France: SESAME 2007, convention # F-08-1097/R and by the Agence Nationale de la Recherche, 09- NANO-008-AXOC.