Remediation of copper-laden water using hemp: coupling two synchrotron analysis techniques to better understand the mechanisms involved

There is growing interest in the use of lignocellulosic materials, such as hemp, as adsorbents to recover copper from industrial waters. While hemp is known to be chemically efficient for such an application, the adsorption mechanism involved have yet to be clearly identified, which is essential to optimize the retention capacity of hemp-based materials.

To obtain this information, researchers from an interdisciplinary team have used two analytical techniques based on synchrotron radiation: X-ray micro-tomography at ANATOMIX beamline and X-ray micro-fluorescence imaging at PUMA beamline. By allowing them to visualize the spatial distribution of copper complexed by three types of hemp shives, the combination of these techniques contributes to a better understanding of the nature of the interactions, physical and/or chemical, involved in the adsorption of the metal.

Hemp shives, a co-product of the hemp industry, are struggling to find a market. However, recent studies have concluded that these materials could be inexpensive, viable and effective adsorbents for recovering and removing metals from polluted effluents. In general, to explain adsorption performance, empirical mathematical models are fitted to measured data, in order to deduce the interactions involved in the adsorption process. It is therefore necessary to complement theory with experiment. To this end, teams from two laboratories in the Franche-Comté region, Chrono-environnement and FEMTO-ST in Besançon, as well as from INRAE in Nantes (BIA) and SOLEIL (ANATOMIX and PUMA beamlines), have chosen to combine various microscopic and spectroscopic techniques.

The aim of their study was to clearly locate the presence of adsorbed copper in three hemp materials: water-washed shives (SHI-WCu), shives activated with sodium carbonate (SHI-CCu), and shives chemically modified with 1,2,3,4-butanetetracarboxylic acid (SHI-BTCACu).

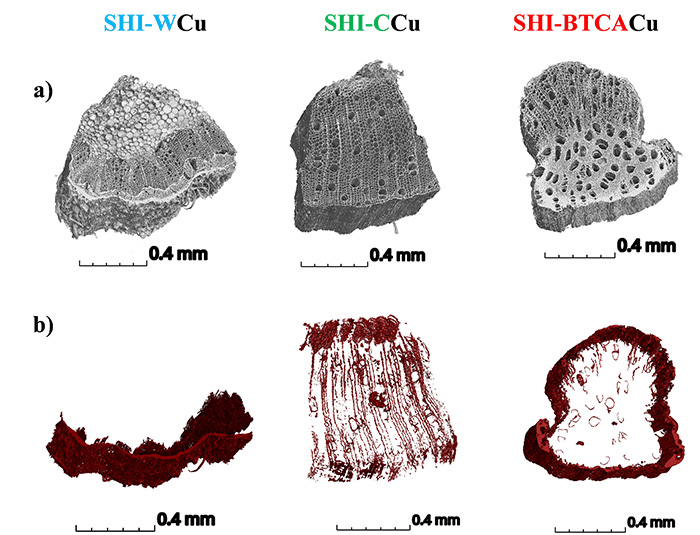

First, micro-tomography images were acquired at the ANATOMIX beamline. Each shive studied was X-rayed using two different photon energies, one below the absorption K-edge of copper and the other slightly above it. By subtracting these images from each other, it was then possible to isolate the copper signal (areas of high luminosity) from that of the lignocellulosic material and obtain a third image showing only the spatial distribution of the metal.

This K-edge subtraction imaging technique was applied to characterize the three shive types. Reconstruction of the 3D images (Figure 1) showed that, for the SHI-WCu and SHI-CCu samples, the metal was distributed over the entire outer and inner surface of the shive, in line with the hypothesis of a diffusion mechanism. On the contrary, for SHI-BTCACu, the copper was located mainly on the outer surface and around the surface of vessels involving carboxylate functions by complexation or ion exchange. These micro-tomography experiments on the ANATOMIX beamline provided valuable 3D information to identify areas where copper was present in significant proportions.

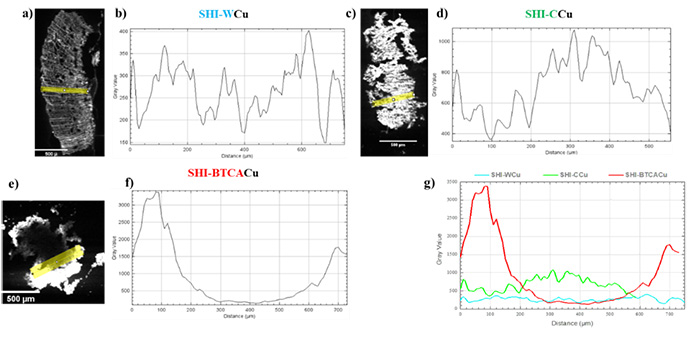

Then, to confirm these results, X-ray micro-fluorescence maps were collected on the PUMA beamline from 20-µm-thick sections (Figure 2). Comparison of the maps showed that, in the SHI-WCu and SHI-CCu samples, copper was distributed over the entire free surface, inside and out, with no obvious zones of preferential accumulation. For SHI-BTCACu, a different distribution of copper was observed, as it tended to be localized at the periphery of the sample, in agreement with the micro-tomography results obtained on ANATOMIX. PUMA data processing also enabled the extraction of a copper distribution profile along a 15-pixel (approx. 75 µm) thick line running radially through the sample. Looking at the profiles, it became clear that, for SHI-WCu and SHI-CCu, the signal was present throughout the area analyzed (area of the rectangle shown in yellow in Figure 2). The metal appeared to be more or less evenly distributed in these samples. For SHI-BTCACu, the copper distribution profile was totally different, characterized, on the one hand, by two zones of high intensity in the outermost parts (periphery) of the section and, on the other, by the absence of signal in the innermost part. These differences in the copper distribution profile in the shives corroborate the two different adsorption mechanisms.

In conclusion, the study benefited from the complementary nature of the two analysis techniques: tomography on ANATOMIX and X-ray micro-fluorescence on PUMA. Tomography provides 3D information but is less sensitive to elemental concentrations, while X-ray fluorescence imaging is more sensitive (lower detection limit) but the reconstruction of 3D images from 2D information is much more complex and time-consuming.

The differences in Cu distribution on the 3 types of shives have enabled the scientists to validate the two proposed adsorption mechanisms: surface adsorption and diffusion for SHI-W and SHI-C, and chemisorption and ion exchange for SHI-BTCA. This precise knowledge of the copper/shive interactions involved is extremely useful for adapting the batch* experimental protocol for industrial water treatment to complex industrial conditions.

* The term ‘batch’ process refers to an industrial treatment in which the finished product is obtained following a series of tasks rather than continuously.