PSICHE: 3D imaging in real time and under extreme conditions

Characterization of materials under high pressure and temperature conditions are of great interest in planetary and materials sciences. Many efforts have focused on the development of in situ three-dimensional (3D) tomographic imaging at extreme conditions which enable nondestructive investigations of heterogeneous structures of materials. The PSICHE team demonstrates the possibility to perform high-speed X-ray tomography at high pressure and temperature allowing complete high-resolution tomograms to be acquired in about 10 s instead of the current state of art of 20 min. This gives direct visualization to rapidly evolving or unstable systems, such as flowing liquids or reacting components, and avoids assumptions in the interpretation of quenched* samples.

X-ray computed tomography (XCT) is the most powerful non-destructive tools for imaging the internal structure of a sample. It is commonly used to study material behavior under stress. XCT is widely applied to quenched samples; however, in situ characterizations may be critical in the cases of non-quenchable phases or dynamic studies where the ‘squeeze, cook and look’ approach is not sufficient. A critical parameter for the accurate characterization of these properties is the time resolution (e.g. acquisition time) at which changes can be observed, detected and/or measured.

The reconstructed 3D image is computed from a series of two-dimensional X-ray radiographs. A set of radiographs are recorded at small angular increments over 180° rotation with respect to an axis perpendicular to the incident X-ray beam. At high pressure 3D imaging is usually performed using a static high-pressure press within which the anvils can be rotated under a uniaxial load transmitted by thrust bearings. Acquisition time for a tomogram in such an apparatus is mainly limited by the difficulty of transmitting the large axial load through the bearings to the rotating anvils and typical acquisition times are of 20 min or higher.

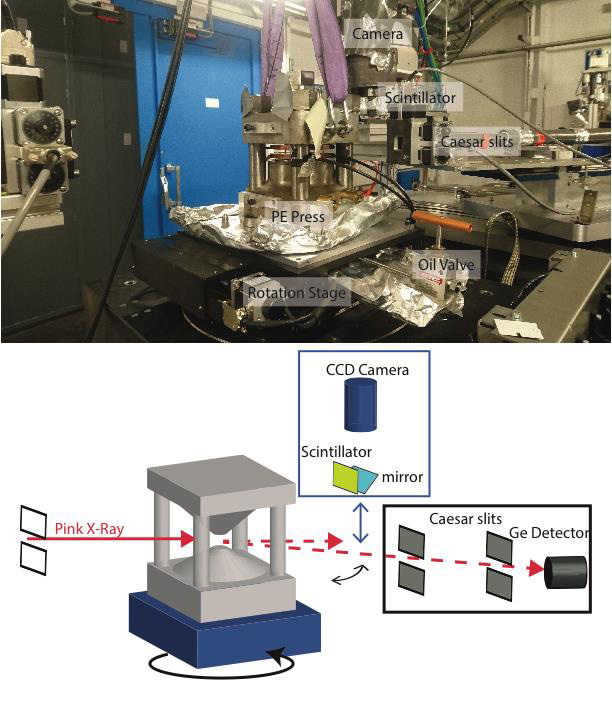

By the use of a high flux pink beam (broad spectral range) through a Paris-Edinburgh (PE) Press, the PSICHE team was able to improve the speed to only 10 s. The PE press is directly installed on the high load – high precision rotation stage of PSICHE beamline (Figure 1). Once pressurized to its target pressure, the press is isolated from the hydraulic line and disconnected, allowing it to rotate freely. High temperature is achieved by thanks to an internal furnace in the sample assembly while the anvils are continuously cooled using a flowing water circuit.

High-speed imaging is particularly necessary for investigating the behavior and properties of liquids: measuring the viscosity, surface tension on a liquid-liquid interface or immiscibility of liquids for example. To demonstrate the potential of the new device, the scientists present first measurements of silicate melt propagation through a solid silicate matrix. Starting materials consisted of a mixture of finely ground natural rhyolitic magmatic rock and roughly ground olivine crystals as a solid silicate matrix. The mixture was pressurized to 3 GPa and then heated up to the melting point of rhyolite (1100 K) mimicking conditions of about 100 km depth. Due to the four columns of the PE press only 135° angular opening is available for a tomographic scan. Applying the algebraic reconstruction technique (ART), an algorithm adapted to restricted angles of visibility of the sample, the3D rendering of rhyolite melt in the sample volume has been reconstructed (Figure 2).

High-speed XCT offers the possibility to observe in real time the evolution of the sample (Figure 3). The scientists were able to observe the movements of liquid through the matrix and crystallization of iron beads. One could measure crystallization rate for example. XCT can be combined with energy-dispersive x-ray diffraction offering the possibility to study material structures at the micro and atomic scales.

This study led to the development of a new press, called UToPEC, which will allow 3D imaging below 10s with a 165 ° view of sample.

* Quenched sample: the sample, first brought to high pressure-high temperature, is brought back to ambient pressure and temperature. The goal is to try to “freeze” the form the sample had under HP-HT conditions, but most of the time it does not work. Hence the need to make measurements in situ, when the sample is at HP-HT.