New insights on aluminium corrosion layers for aircrafts’ preservation

Since the 1920’s, aluminium alloys have been widely used in the fields of transport and architecture. Unfortunately, those alloys are very sensitive to the corrosion phenomenon. It is therefore paramount to fully understand those phenomena to preserve the important number of aluminium artefacts registered in museum collections, such as air and space museums. Scientists from the Research and Restauration Center of French Museums (C2RMF), PSL Research University, the Jean Lamour Institute (CNRS/Université de Lorraine) and the SOLEIL synchrotron used the LUCIA beamline’s X-ray to get new information about the components of those corrosion layers.

For these ‘aeronautic’ alloys, the corrosion behaviour is related to the presence of intermetallic phases in the Al matrix mainly composed of aluminium, copper, manganese/iron and magnesium. Due to the presence of the thick corrosion layer, conservators and curators are most of the time destitute in front of those altered aluminium materials. To get a clear evaluation of the risks encountered by aluminium-made collections and to propose the development of coherent conservation strategies, the effect of the thick corrosion layer on the corrosion rate of the underlying metal has to be understood. Only a few studies are related to the characterization of the corrosion products formed after long term exposure.

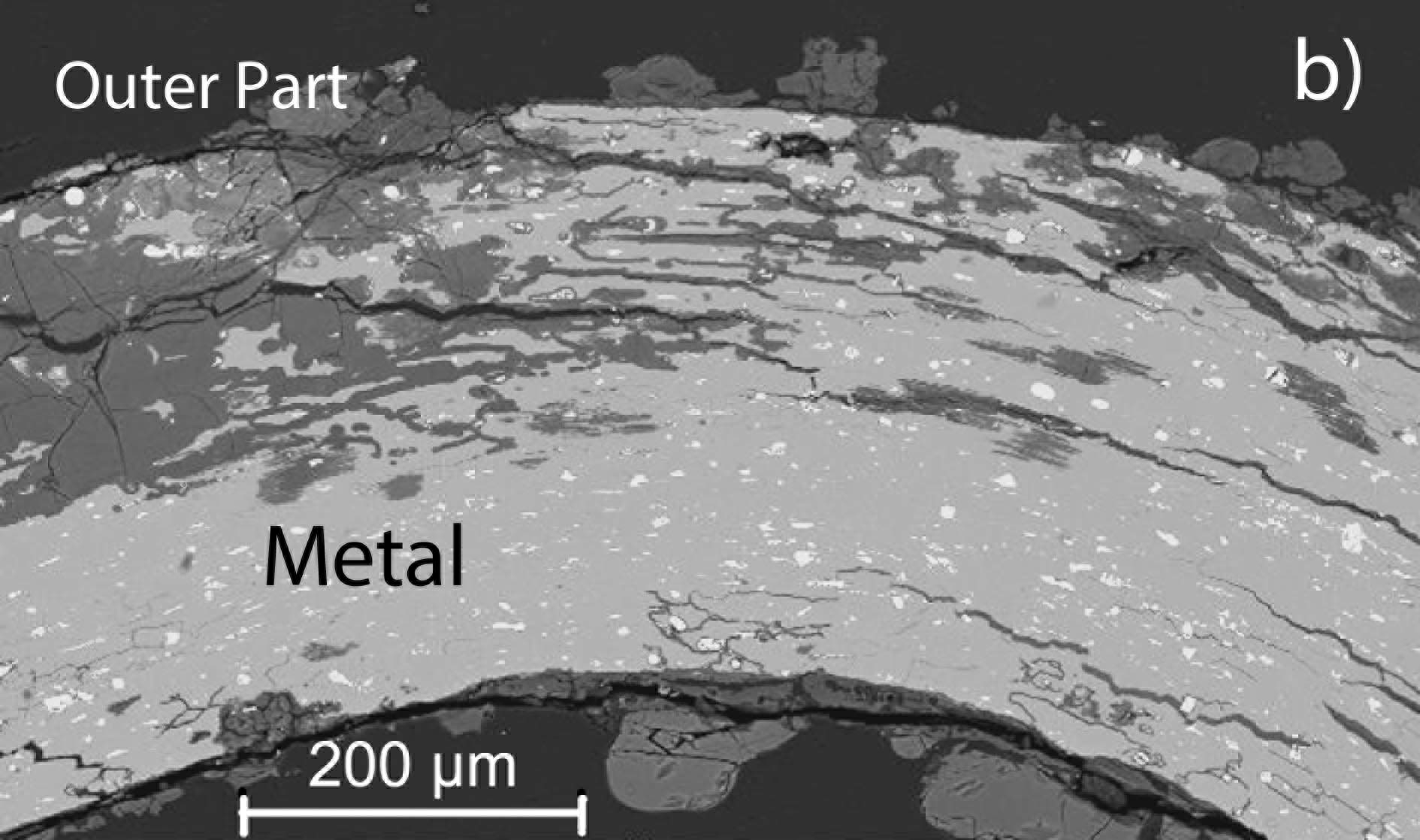

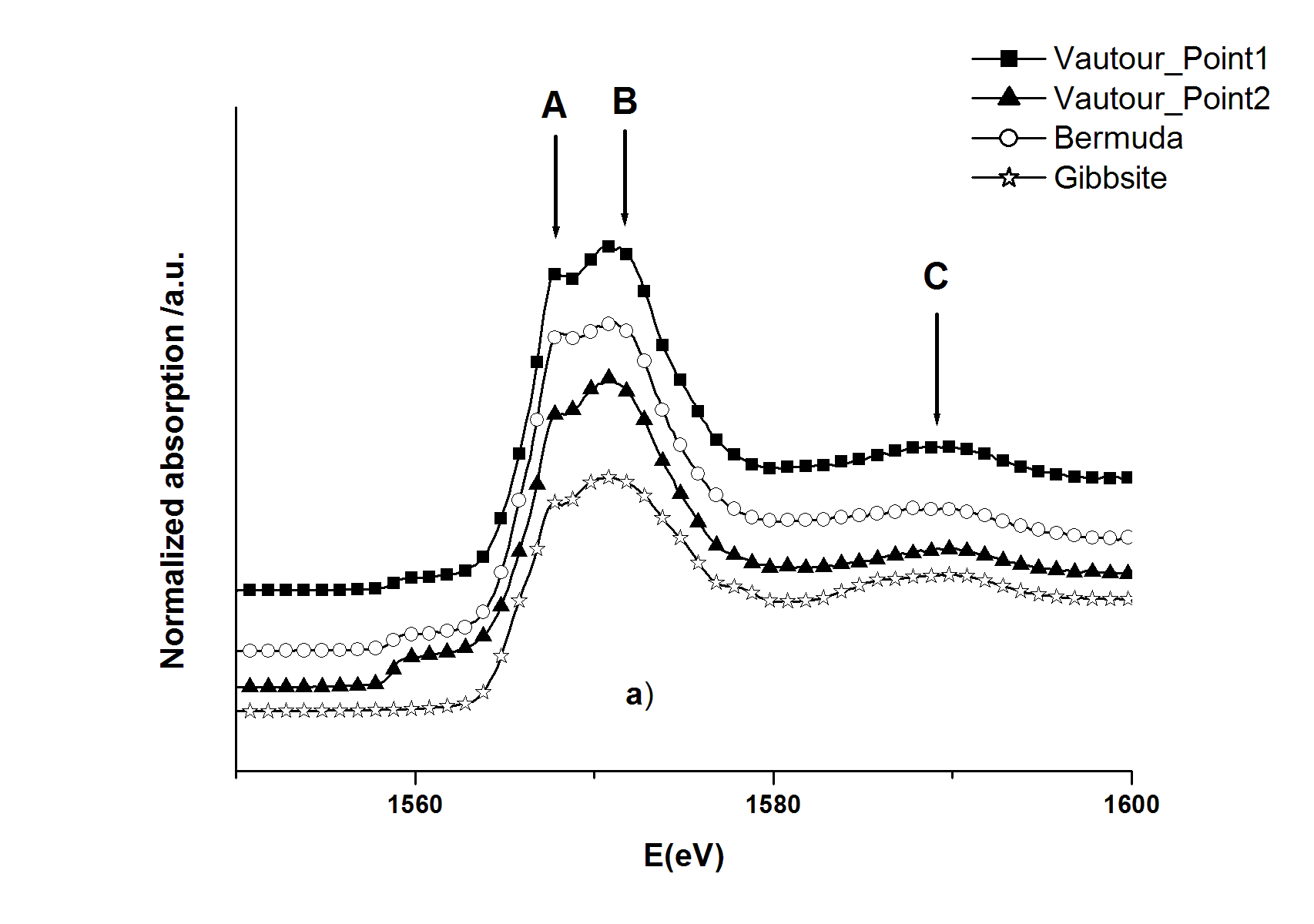

To ensure the preservation of aluminium made materials it is necessary to obtain information on the physicochemical characteristics of the corrosion layers. To reach this goal, samples were collected on various ancient aircrafts built in the 1930–1980 period, belonging to French “Musée de l’Air et de l’Espace”. After analysis of the metallographic cross-sections, the structure of the corrosion products was characterized by XANES to describe the chemical environment of Al atoms in the corrosion products at a microscopic level. Experiments have been done at the LUCIA beamline, a perfectly suited beamline to collect those data with high spatial resolution and high sensitivity at the Al K-edge.

µXANES analyses provide for the first time new information about the nature of the phases constituting the corrosion system formed over a long term under atmospheric corrosion for different ancient aircrafts. The data recorded have confirmed that corrosion products in these thick layers are mainly composed of poorly crystallized or amorphous phases in which the Al is six fold coordinated and no associated four fold coordinated aluminium has been detected. In general, the structures of the spectra collected are very close to the spectra of two main reference compounds, gibbsite and boehmite, used as fingerprints. Other spectra with an intermediate feature of the two reference phases have also been recorded. These spectra exhibit the same features as the ones recorded for hydrous aluminium oxide (Al(OH)3-xH2O) type materials observed by after accelerated ageing of anodized layers on aluminium. In the corrosion layer, the distribution of the 3 groups of aluminium oxyhydroxide phases identified is homogeneous at a large scale and explains that all the corroded Al alloys have almost the same corrosion behaviour. In particular, the presence of thick corrosion layers does not lead to strong modifications in the electrochemical behaviour of the remaining metal.

The use of µXANES experiments at the LUCIA beamline has shed new light about the organization of the thick corrosion layers and on their component phases. This is a key factor to model the behaviour of the phases during the ageing process and finally to propose new protection systems based on the stabilization of the aluminium hydroxide compounds versus the hydration processes.