A new detector on DIFFABS for fast measurements of X-ray diffraction images

Following a joint project undertaken by the ImXPAD Company and SOLEIL with a development time of more than three years, a ‘CirPAD’ detector was installed in May 2018 on the diffractometer of the DIFFABS beamline. Of circular shape, X-ray diffraction measurements can be taken over an angular range of nearly 140° in a single acquisition step, which will greatly decrease the data acquisition time. This issue, associated with the fact that the detector is two-dimensional, will make possible diffraction experiments, which until now could not have been performed on the beamline.

The CirPAD, funded by SOLEIL and the Région Centre (administrative region of France) will be made available to users from the next projects call (submission of projects in September 2018 for a beamtime allocated from March 2019).

The manufacturing of the detection modules (20 in total) as well as the associated electronics was done by ImXPAD. The mechanical part of the detector was developed at SOLEIL. This work involved a tight collaboration and exchanges between the DIFFABS beamline team and work-groups Detectors, Engineering, Alignment, Coordination, Multidisciplinary Operations and Control and Data Acquisition Information Technology.

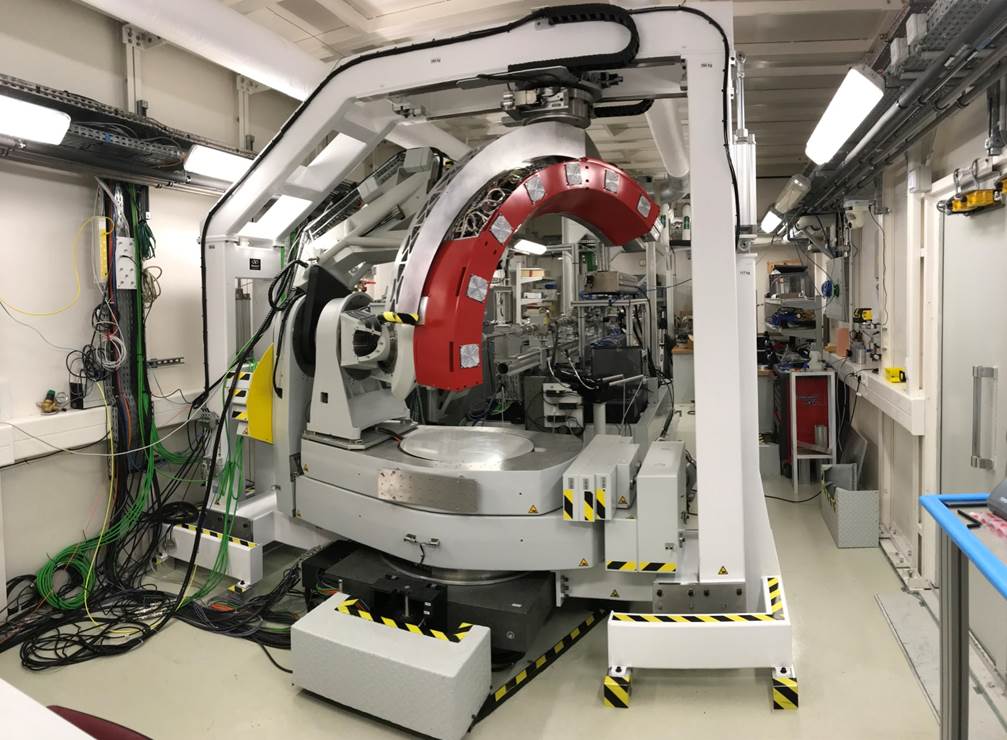

The CirPAD weighs more than 100 kg. Consequently, it was necessary to develop a metal frame to which the detector is attached so that deformations due to the weight do not occur. The frame carries motorisation as well so that the CirPAD can be positioned as required by the experimental conditions. This equipment also includes a mechanical span to which the CirPAD will be fastened. The frame was constructed by the company MicroContrôle, who also supplied the diffractometer 12 years ago.

The detector comprises an assembly of 20 hybrid pixel array detector (XPAD) modules, positioned such to minimise the inter-module spacing (zones in which the X-rays diffracted by the sample being studied are not detected) – these ‘dead zones’ are limited to just 7 pixels per module. Other information: CirPAD has a total of more than 1.3 million pixels, with a pixel size of 130 x 130 µm2.

The circular shape of the detector, associated with an optimized electronics, enables very fast diffraction measurements on extended, with an acquisition time of the order of 2 msec and read times of about 1 msec. This will correspond to a reduction in the measurement time by a factor of approximately 300 compared to the previous detector configuration.

The CirPAD is currently in commissioning phase, and it is planned to be operational and available to users in February 2019. It will represent an additional benefit, for example during investigations into textured materials, for two-dimensional measurements or during monitoring of the change of a sample, such as the supercooled state of materials, involving reduced acquisition times, or for phase transitions (ex. Amorphous/crystalline) during in situ annealing & solid state reactions.