MOFs take center stage with the 2025 Nobel Prize in Chemistry — and at SOLEIL, too!

When a rigid aluminum-based MOF becomes flexible... Long considered rigid by the MOF (Metal–Organic Frameworks) research community, the aluminum-based material DUT-5(Al) has now revealed a remarkable and tunable flexibility depending on the morphology of its particles.

Researchers from the Institut Lavoisier de Versailles (ILV) and their collaborators have demonstrated this unexpected behavior, recently published in ACS Applied Materials & Interfaces. This work resonates strongly with the 2025 Nobel Prize in Chemistry, awarded for groundbreaking advances in the field of MOFs.

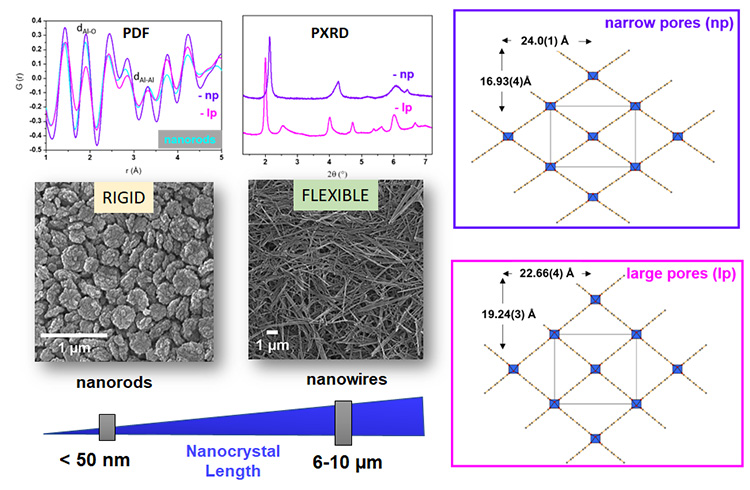

Using an innovative synthesis strategy based on graphene oxide nanoscrolls—graphene oxide sheets rolled into spiral, open tubular structures—as structure-directing agents, the team succeeded in producing DUT-5(Al) nanowires longer than 6 μm. These nanostructures exhibit reversible structural flexibility upon guest molecule adsorption, in contrast to shorter nanorods, which remain rigid.

Among the various techniques employed to investigate this unexpected behavior, synchrotron X-ray diffraction and scattering experiments performed on the CRISTAL beamline at SOLEIL enabled scientists to monitor, with exceptional precision, the subtle structural transformations occurring in the material.

These findings open new perspectives for the design of MOFs with controlled flexibility, tailored for applications such as gas separation, catalysis, or chemical sensing.

The contribution of the CRISTAL beamline to the field of MOFs is undeniable: since SOLEIL’s opening to the scientific community in 2008, numerous experiments—notably by ILV researchers—have shed light on the crystalline structures of many MOFs.