Natural rubber: strain induced crystallization studied under X-ray

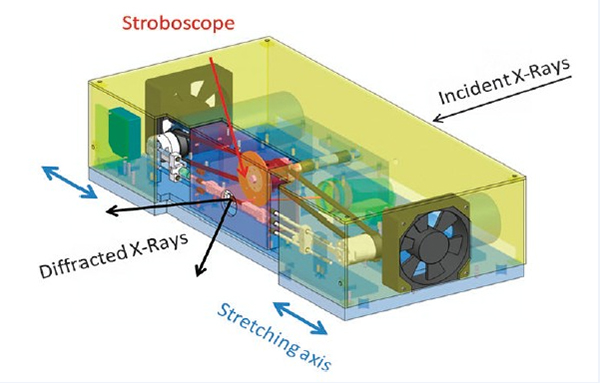

Strain induced crystallization is a complex phenomenon whose characterization is paramount to understand the mechanic properties evolution of some materials. Its analysis requires specific characterization techniques. Scientists from the University of Lyon and INSA Lyon used the DIFFABS beamline at the synchrotron facility SOLEIL to highlight the importance of the solicitation frequency, the environmental temperature, and the stretching ratio on the kinetics of the natural rubber (NR) crystallization.

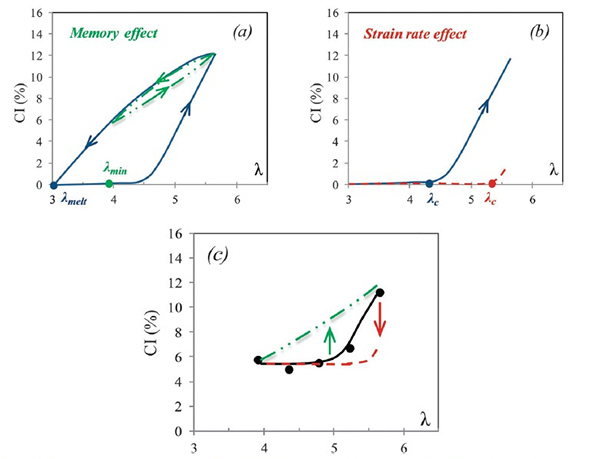

(a) Schematic evolution of CI versus λ for a slow strain rate cycle perdormed with λmin < λmelt, (solid line) and for a slow strain rate cycle performed with λmin > λmelt, (double dotted line).

(b) Schematic evolution of CI versus λ for a monotonic loading at a slow strain rate (solid line) and a high strain rate (dotted line).

(c) Crystallization curve obtained during the loading step of teste C performed at 2 Hz (data points and solid line). Schematic evolution of the crystallization curve of a slow strain rate cycle performed above λmelt, (double dotted line) ans during loading at a high strain rate (dotted line).

Several tests have been realized, playing not only on the stretching ratio λa and the frequency, but also on the sample temperature. In all cases, an increase of the frequency was associated with a decrease of the SIC phenomenon. Those experiments also led to more unexpected conclusions regarding the rubber’s reaction under low frequency (2 to 5 Hz). When λmin (smallest stretching of the cycle) is above λmelt(melting stretching ratio), a memory effect related to chains orientation enhance the crystallization. Thereby, the NR retains its excellent mechanical properties. When cycles are realized at the stretching ratio λminbelow the melting deformation λmelt, combined effects of self-heating and nucleation speed of the crystallites lead to the progressive vanishing of the crystallinity with the frequency.

Before this study, similar works had been conducted but none were equipped with ad hoc equipment. They were only investigating rubber’s behavior at the lowest frequencies (~0,001 Hz). These experimental data highlight the complexity of strain induced crystallisation. A physical model coupling the mechanics, thermic and thermodynamics would be able to provide a pertinent description of this phenomenon.