Lessons on textile history and fibre durability from a 4000-year-old Egyptian flax yarn

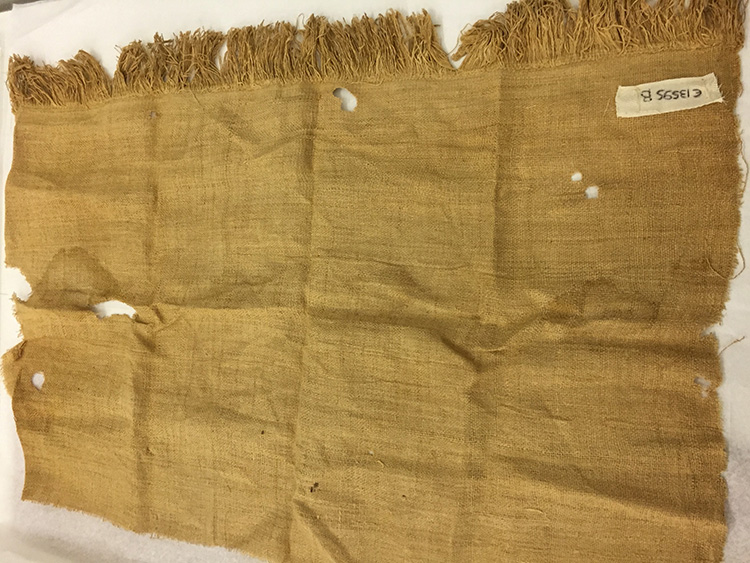

Ancient Egypt laid the foundations for the cultivation of flax as a textile fibre crop, particularly for making funeral cloths and mummy strips for high society. Today, flax fibres are used in high-value textiles, as well as reinforcements in composite materials. Flax is therefore a bridge between ages and civilizations. Here, a yarn from an Egyptian mortuary linen, dating from the early Middle Kingdom (2033 - 1963 BCE), was examined using advanced techniques, such as nano-tomography, biphoton excitation microscopy, and atomic force microscopy, and compared to a modern flax yarn. The final objective is to address understanding elements about both ageing and durability of flax fibres.

Amongst all the plant fibres used today for textiles, papers and composite, flax has a long and fascinating history. Geographically, it is in the Fertile Crescent that the oldest traces of flax seeds or capsules, and such evidence of the domestication of this plant, have been found. However, the most beautiful pieces date from Ancient Egypt as their highly-preserved state a result of their optimal conservation over millennia in sarcophagi or tombs with remarkably stable moisture and thermal conditions, as well as sheltering from UV light.

For several decades, the development of non-destructive analysis techniques has led to numerous works on the conservation of ancient textiles, including linen. Optical, infrared or vibrational spectroscopy techniques have been used extensively. These studies have shown that such ancient plant fibres preserve well. This is in spite of morphological and structural defects that are often more pronounced than on modern fibres, and may be attributed to possible deterioration linked to the conservation of the samples. These studies principally focus on imaging and biochemical composition of the historic samples. Conservation of mechanical performance and the microstructural differences between ancient and modern varieties, and whether these differences are linked to the genetic heritage or to the method of crop cultivation or fibre, have not been examined. Here, we evaluated an ancient flax yarn from the early Egyptian Middle Kingdom and a modern flax yarn using advanced, non-destructive imaging methods to study differences (and similarities) in their morphological, microstructural and mechanical characteristics. The study was conducted with the support of complementary teams from a range of French (IRDL CNRS Institute, Synchrotron SOLEIL, INRAe, FEMTO, LMGC, Musée du Louvre) and English (University of Cambridge) museum and research institutes.

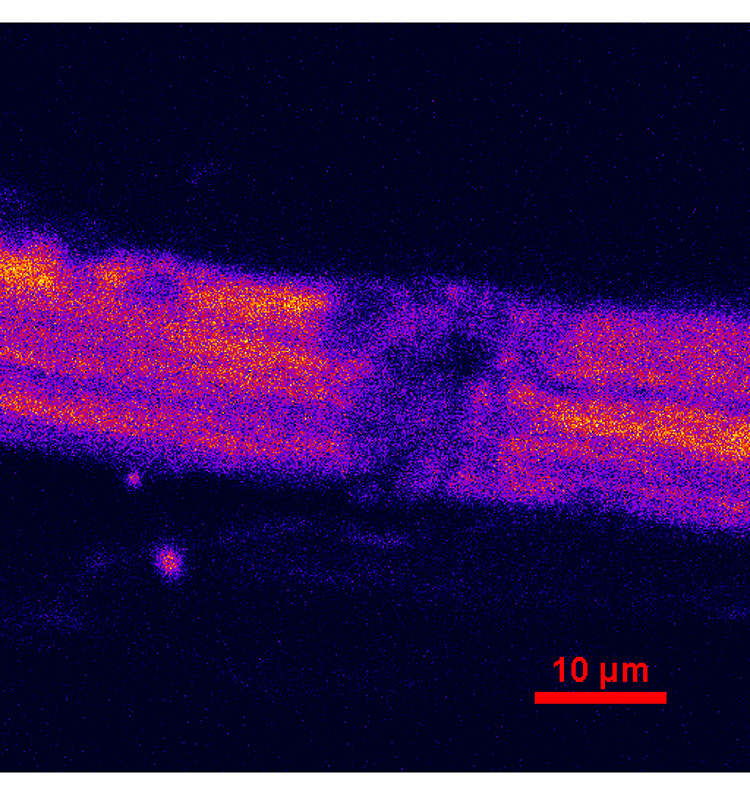

The contribution of Synchrotron SOLEIL was addressed through the DISCO Beamline and in particular thanks to its bi-photon microscopy facility. The second harmonic generation (SHG) microscopy is able to provide suitable and of interest informations about the microstructural arrangement of cellulosic cell walls such as flax fibres.

Our structural examination of 4000-year old Egyptian flax fibres in comparison to modern flax fibres has offered a number of insights on the textile know-how of the Egyptians, as well as on the temporal evolution of flax fibres. The fine, highly-individualised and residue-free flax fibres obtained through water-retting allowed the ancient Egyptians to make soft and luxuirous quality textiles despite fully-manual processing. While nano-mechanical measurements at the cell wall scale show stiffness of old fibres quite comparable to those of modern fibres, at the fibre scale, larger presence of structural defects – stress-concentrating kink-bands with low cellulose crystallinity – is notable on the old, fragile fibres. To improve durability at the fibre scale, producing fibres with low quantities of defects is necessary, in particular if they are to be used as reinforcements of next-generation environmentally-friendly composite materials.