Evidences of the self-assembly of graphene oxide sheets at the air-water interface

The interest given to graphene oxide has risen since few years, especially for its use as a precursor for graphene, which application field gets broader and broader. In this framework, producing graphene oxide films with controlled density and thickness is a major challenge. One way to do so is to spread the graphene oxide flakes at the air-water interface (Langmuir films).

In a study carried out at Synchrotron SOLEIL and ESRF, scientists from Paris 6 University, ECE (Paris) and University of Saragoza determined for the first time the microscopic structure of these graphene oxide films at the water surface.

By spreading the graphene oxide flakes at the air-water interface, the formed films have the advantages of having an easily controlled density, and of being transferable on solid substrates. However to gain further insights on the deposition process, the structure of the film at the water surface (before transfer) has to be understood and compared to the one obtained on solid substrate (after transfer).

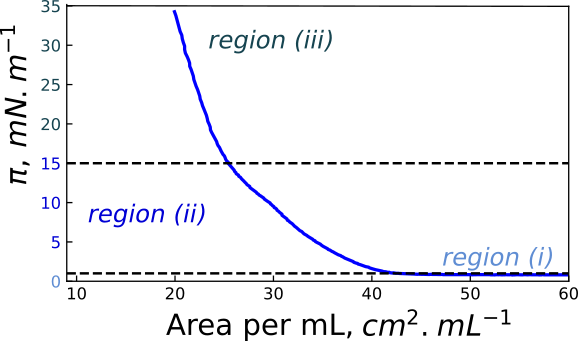

The measurement of the surface pressure with respect to the surface density allows to follow the evolution of the graphene oxide films at the macroscopic scale. A characteristic measurement, performed at fixed temperature, is shown on the Figure 1 (isotherm p-A). Three regions can be identified. The first, at zero surface pressure, corresponds to the coexistence between two phases, the graphene oxide flakes are not yet covering the whole surface. The second region, up to 15 mN.m-1, is identified as the percolation of the graphene oxide sheets, and the third region, which compressibility is the lowest, is associated to the compression of a homogeneous film.

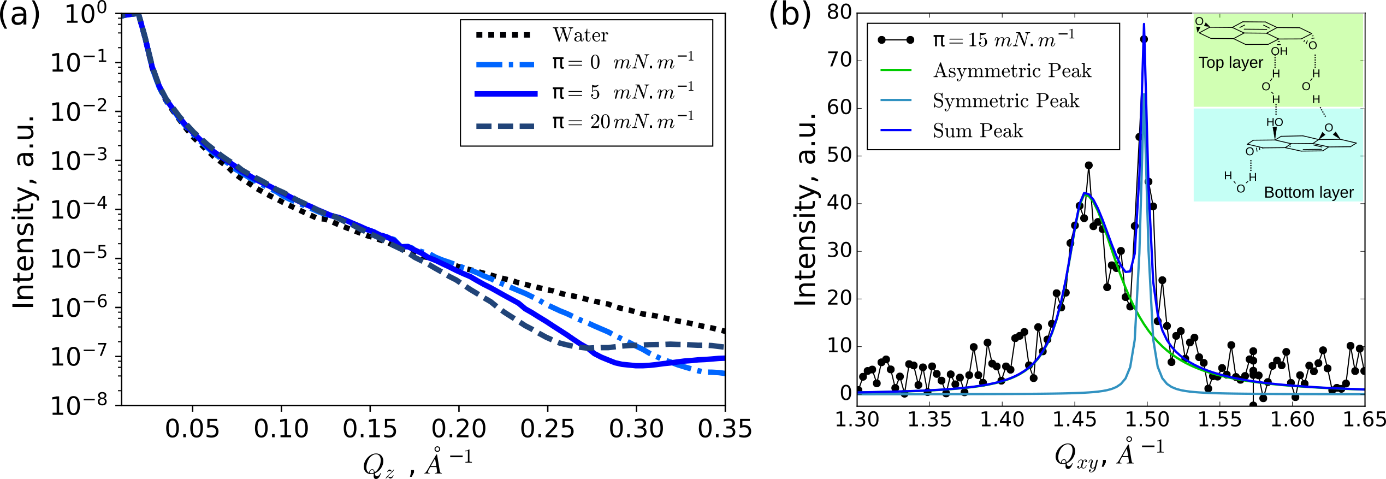

We studied the structure of the film at the air-water interface at the microscopic scale, through Grazing Incidence X-Ray Diffraction (GIXD) measurements on the SIRIUS beamline of thse SOLEIL synchrotron, coupled to X-Ray Reflectivity (XRR) performed on the ID10 beamline of the ESRF synchrotron. These measurements are shown on the Figure 2. The thickness of a single graphene oxide sheet is of about 10 Å. However, to fit the reflectivity spectra, a layer of about 20 Å is needed for every surface pressure values. This indicates that the film spread at the air-water interface is composed of a bilayer of sheets (as represented in the inset of Figure 2 (b)). The GIXD measurements validate this hypothesis. Indeed, the shapes of the two diffraction peaks observed at non zero surface pressures indicates the presence of two different structures. One of them is composed of sheets lying parallel to the water surface (symmetric peak) and the other one is composed of disoriented sheets (asymmetric peak). This bilayer structure can be understood with the presence of water molecules intercalated, linked to the sheets of each layer through hydrogen bonding. When the bilayer is compressed, the sheets parallel to the water surface reach fast a high density while the sheets of the upper layer gets more disoriented as the surface pressure increases.

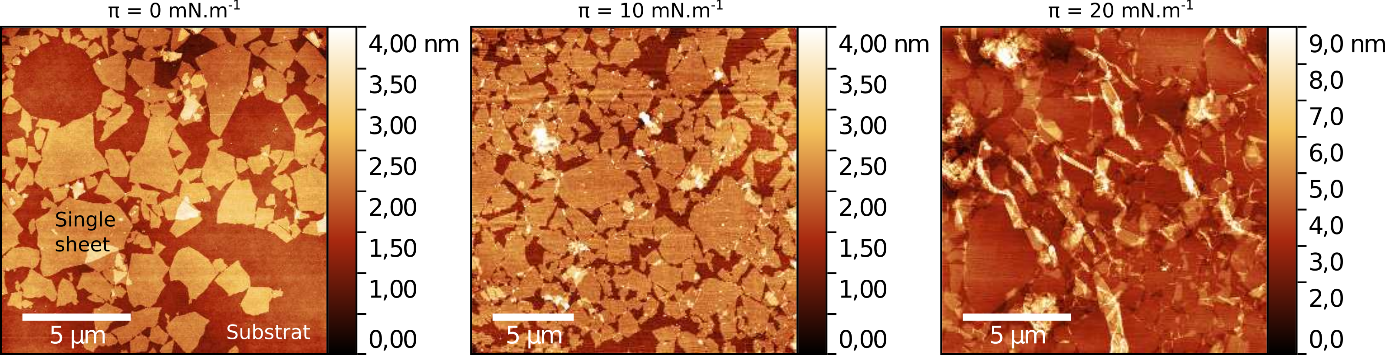

The measurements of X-Ray diffusion at the air-water interface allowed us to interpret the plot represented on: the XRR evidences the presences of two different layers and the GIXD shows the disorientation of the sheets in one of the two layers. At the water surface, we observe the spontaneous formation of a bilayer of graphene oxide sheets. The organizations of the two layers get different during the compression. However the observation made after the AFM measurements on transferred films indicates a thickness corresponding to a monolayer (as shown on Figure 3). This demonstrates that the transfer mechanism is more complex for this system than for the more “usual” Langmuir monolayers. A difference in the amphiphilic nature in the graphene oxide sheets composing each of the layers could explain this phenomenon.