Sustainable development and the pulp and paper industry – A second life for ashes from co-combustion of bark and sludges

Recycling of Phosphorus (P) from waste streams needs to be increased for a sustainable society. The pulp and paper industry produces large amounts of nutrient (notably P)-rich sludges. Swedish researchers have now published a detailed characterization of ash* from co-combustion of bark and sludges from a paper mill. Morphological parameters and porosity were analyzed with X-ray micro-tomography at the ANATOMIX beamline. The results of the study indicate that the slag* could be used for soil fertilization purposes, after being pretreated by crushing.

Recycling phosphorous from waste streams for fertilization purposes could contribute to a sustainable society. The production in the pulp and paper industry results in several waste streams, e.g. nutrient-rich sludges in different forms (phosphorous but also nitrogen, potassium, and micronutrients like magnesium, zinc, cupper...). The study aims to investigate possibilities for utilising nutrient-rich ash fractions from the combustion of bark and two types of sludges, which are residuals streams from the pulp and paper industry. The combustion performance was investigated, and advanced analysis methods were used to characterise the ashes, including evaluating morphology, porosity, pore size distribution, active surface area, elemental composition, and crystalline phases.

This was a collaboration between the Thermochemical Energy Conversion Laboratory at the Department of Applied Physics and Electronics, Umeå University, and Department of Forest Biomaterials and Technology at Swedish University of Agricultural Sciences, Sweden. The tomography experiments were performed in collaboration with the team at the beamline ANATOMIX of Synchrotron SOLEIL.

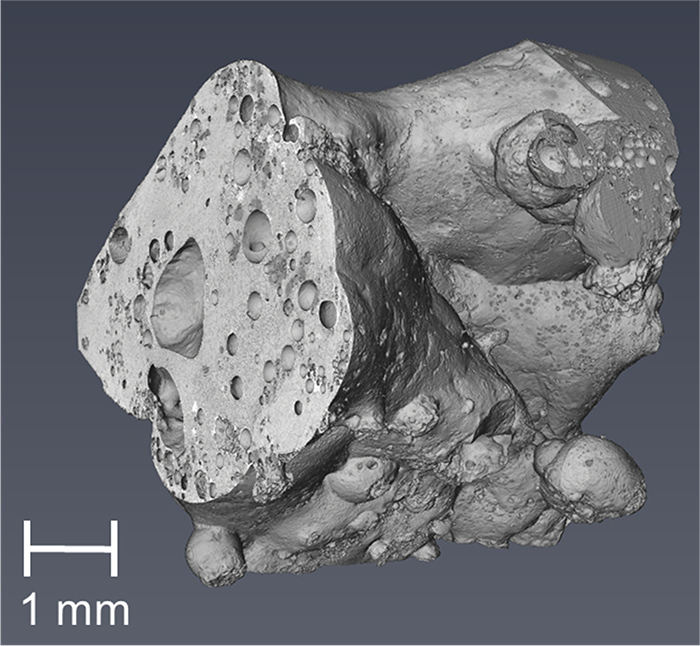

Although slag was present in all experiments, the share of bottom ash found as slag particles increased with higher sludge proportion in the fuel blend. Nutrient amounts indicate that slag particles from combustion of sludge and bark mixtures can be useful either as a soil improvement directly or for recovery processes. Evaluation of tomography data showed that discrete and open pores could be distinguished on a micrometre scale. The porosity of the slag varied between 17 and 23 vol% for the bark and sludge mixtures. Open pore volume displayed large variations, 39–56 vol% of the pores were open pores connected to the surrounding volume. For all samples, 90 % of the pores were small, with an equivalent diameter under 30 μm, but the largest pore volume consists of pores with diameter over 75 μm. In soils, pores with a minimum diameter over 30 μm generally transmit water and the smaller pores store water. The slag particles have relatively thick walls, with few pore openings to the surroundings.

Tomographic analysis of morphological parameters was performed at the beamline ANATOMIX. A measurement strategy for heterogeneous sample type containing highly absorbing regions (Fe-rich) and C-rich regions with very low X-ray absorption was developed together with the beamline scientists, including testing of different detectors and measurement distances to obtain clear images of microporosity.

Conclusions

The amount of nutrients in the slag from the combustion experiments indicates that the slag is a candidate material for further investigations on soil improvement. Morphology of slag particles was analysed with X-ray micro-tomography and image analysis. The porosity and open pore volume of the slag displayed a large variation between within as well as between fuel mixtures, with a porosity between 17 and 23 vol% for the bark and sludge mixtures and in average 39–56 vol% was open pore volume. The number of discrete pores per particle volume is overall high and the largest number of discrete pores were small pores, under 30 µm in diameter, while the largest pore volume consisted of large pores over 75 µm in diameter. Overall, the slag particles have relatively thick walls, many small discrete pores and with few pore openings to the surroundings, indicating that the slag needs to be ground before application in the soil to improve the root access to the nutrients.

*Ash/slag: Ash as a general term is comprised by fine, powdery material (ash) and larger particles even up to the size of a fist from the combustion system used in this work (slag). Slag is formed when the share of liquidus phase in the total ash is too large and the individual smaller grains adhere together into a mixture of melt and solids. When this solidifies you get slag which contains crystallites of stable compounds, amorphous material, and voids.