In search of the tools of the first bronze craftsmen in western France

The invention and diffusion of copper and bronze metallurgy in Europe constituted a true technical innovation for societies in the middle of the 3rd millennium BC. On the archaeological sites of western France, the techniques of metal production and the manufacture of prestigious objects such as tools remain largely unknown. Thanks to a collaboration between archaeologists from the Trajectoires and CReAAH laboratories, from Inrap and Eveha, and the DIFFABS beamline, use-wear analyses combined with XRF analyses have made it possible to identify the first stone tools used for the production of metal objects in Brittany.

The emergence and development of copper and bronze metallurgy is a major archaeological challenge for the study of Late Neolithic and Early Bronze Age societies in Western Europe. From the middle of the 3rd millennium B.C., this technical innovation profoundly restructured the networks of population circulation and exchange of goods, which now include ores and metal objects. However, the remains of mining activities and metallurgical production workshops remain particularly rare on the scale of the Atlantic coast, especially in the Armorican Massif. The discovery of direct or indirect evidence of metallurgy, such as crucibles, molds or furnaces, is crucial for these periods.

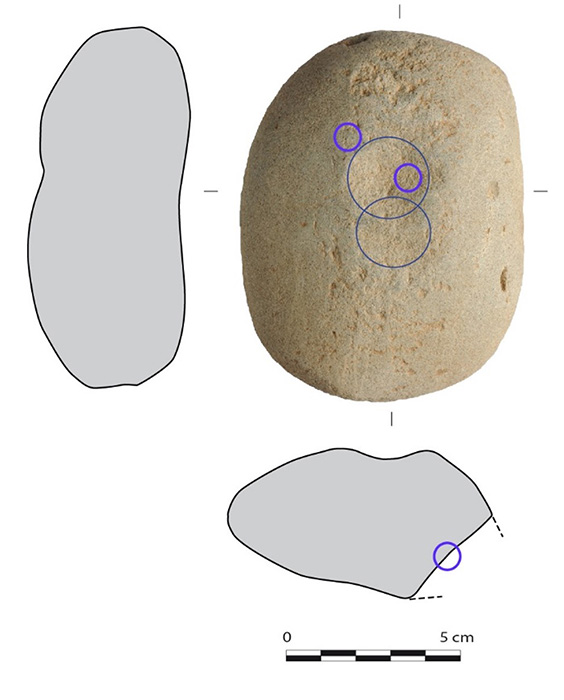

Thanks to a collaboration between archaeologists from the Trajectoires and CReAAH laboratories, Inrap and Eveha, analyses have been carried out on stone tools from several Early Bronze Age settlements in Brittany. These tools were potentially involved in the production of metal objects.

A combined analysis strategy has been set up in order to determine precisely the function of the stone tools, through the analysis of microscopic traces (use-wear analysis) and elemental analyses by X-ray fluorescence spectroscopy (XRF) of possible residues related to their use. The use-wear analysis, carried out with a stereomicroscope and a metallographic microscope, allows us to observe and interpret the traces of use on the archaeological tools by analogy with references constituted by experimentation. The elemental analyses by XRF were conducted with two measurement modalities: with a portable instrument (pXRF) and under Synchrotron radiation (Sy-XRF).

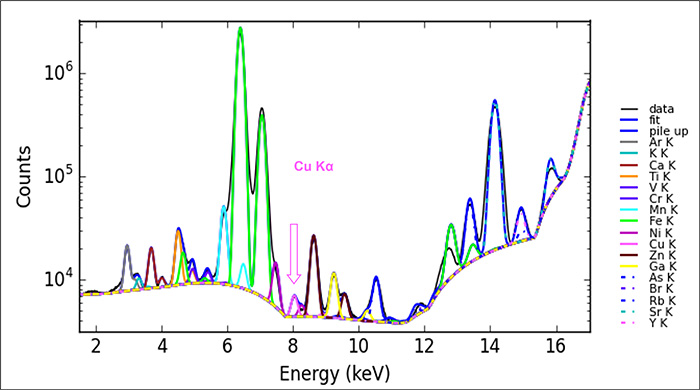

Sy-XRF measurements were performed on the DIFFABS beamline using an 18 keV X-ray beam. The beam size was reduced to 50 µm using a molybdenum pinhole. A fast two-dimensional scan of the tool allows to obtain a mapping on almost the whole object, with a measurement step of 50 µm. An XRF spectrum is acquired for each pixel of the mapping and analyzed to deduce the elements present.

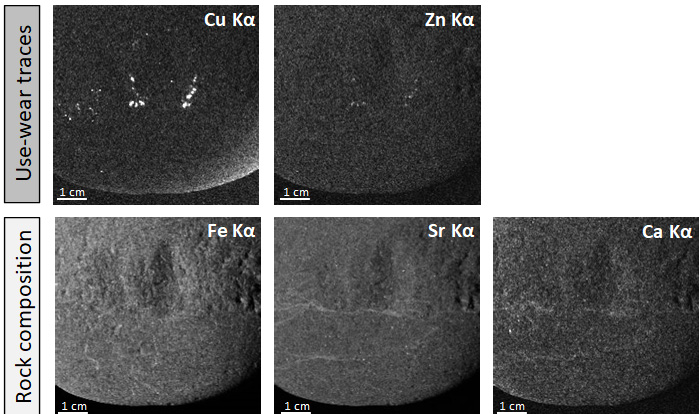

The analytical precision of this Sy-XRF analysis, thanks to the mapping of the distribution of the different atoms, with a resolution of a few tens of micrometers, allows to distinguish chemical elements from the minerals composing the heterogeneous rocks, generally used for stone tools, from the residues of the transformed materials trapped on the surface. XRF mapping has thus shown that residues of copper materials were associated with microscopic traces related to the use of stone tools.

The analysis thus reveals that different stone tools were used on Early Bronze Age sites at different stages of metal tool production and maintenance, from ore crushing to object shaping and blade sharpening.