A nanoporous solid for more efficient cooling

Heat recovery (solar energy, heat pumps, air conditioning, cooling...) has become a technological challenge of increasing significance in this era of awareness of the importance of sustainable development and reducing energy consumption. While the recovery/release of water by nanoporous solids is a particularly appropriate means of achieving this, developing energy efficiency in existing processes remains a challenge.

Researchers from the Paris Porous Material Institute and the Institute for Molecular Chemistry and Material Sciences - Institut Charles Gerhardt Montpellier have created a new hybrid nanoporous material, robust and synthesized under "green chemistry" conditions, and more efficient than the best currently available water adsorbents with a high storage capacity and a lower regeneration temperature.

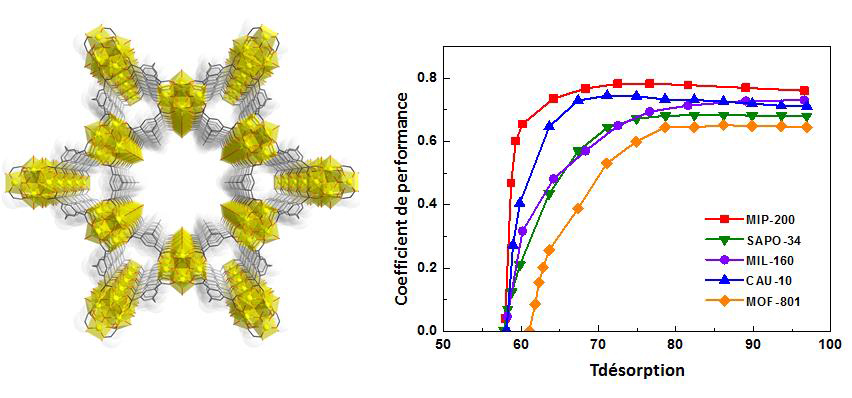

The three-dimensional atomic scale structure of this nanoporous material was determined on the PROXIMA-2A beamline at SOLEIL, by X-ray diffraction from a single micro-crystal of the material.

The use of water adsorbents in the recovery of heat sources from industrial processes or from solar energy (i.e. molecules capable of fixing water at their surface) is promising. The typical temperature of hot water generated in homes with heating co-generators does not exceed 63°C and can be used for cooling systems or heat pumps. Current systems use inorganic porous commercial solids (zeolites or similar), but these have high regeneration temperatures (> 75°C) and a limited pore volume exhibiting poor energy efficiency.

In order to overcome these limitations, teams of researchers from the Paris Porous Material Institute (CNRS/ENS Paris/ESPC/Paris PSL Université) and the Institute for Molecular Chemistry and Material Sciences - Institut Charles Gerhardt Montpellier (CNRS/ENSCM/ Université de Montpellier), in collaboration with the Institut Lavoisier de Versailles, the Korea Research Institute of Chemical Technology and SOLEIL, have designed a new large-pore hydrophilic nanoporous hybrid solid based on zirconium oxoclusters - Zr-MOF (Metal-Organic Framework), which combines a set of parameters leading to greater water adsorption performance for the intended application.

In the case of cooling processes, performance depends on both evaporation and condensation water temperatures, but also on adsorption (exothermic) and desorption (endothermic) water temperatures. The adsorbent parameters to be considered are (among others) the storage capacity, the stability, the heat exchange, the temperature and the adsorption and desorption kinetics. The three-dimensional crystalline structure demonstrates that this new zirconium-based MOF type material, called Zr-MOF or MIP-200, has two types of nanopores that are very stable in the presence of water. The nanopores also have a pronounced hydrophilic character enabling significant heat exchange and sufficiently large diameters (0.7 nm and 1.3 nm) to allow both the adsorption of large quantities of water, but also a desorption at a lower temperature during the regeneration step (<65°C). Energy performance coefficient calculations (the ratio between the energy removed by the evaporator divided by the energy required for regeneration of the adsorbent) conducted by researchers at the Korea Research Institute of Chemical Technology (KRICT), revealed that this solid is more efficient than the porous materials evaluated so far for this type of application, making it possible to envisage the development of a new generation of cooling processes to recover both solar energy or heat sources related to human activity.