How was ancient armor made? A case study on the productions of a famous 16th century Nuremberg workshop

For several years, interdisciplinary research on weaponry has been carried out in order to question the place of weapons in ancient societies through the study of materials. Physicochemical analysis methods make it possible to study the nature and origin of the materials used as well as technical knowledge. When written records are lacking, this is crucial data from the point of view both of the history of art and of the history of economics and techniques.

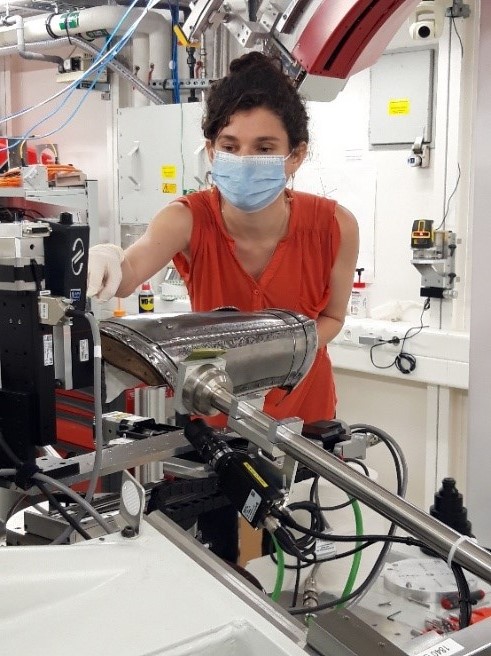

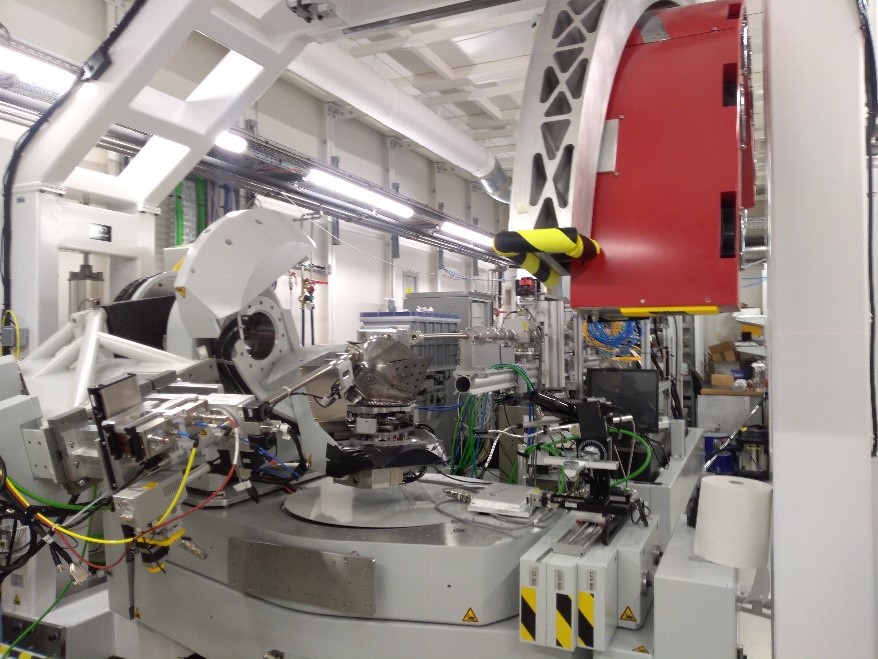

In this context, several pieces of Nuremberg armor from the collections of the Musée de l'Armée and a large suit of armor from the Musée des Beaux-arts de Rennes have been studied by X-ray diffraction on the DIFFABS beamline at SOLEIL.

Until now material studies of ancient armor were limited to metallographic analyses, which consist in determining the microstructure of polished metal samples by observation with an optical microscope. These -investigations have revealed the use of ferrous alloys with various carbon contents, as well as specific heat treatments to harden the metal. These analyses give precious information on the nature of the alloys used, but they have a disadvantage: they require to remove samples of a few millimeters from the objects, samples which can obviously only be taken from the most hidden places of the pieces. In addition, -they can only give a partial view of the nature of the materials at the scale of the complete pieces.

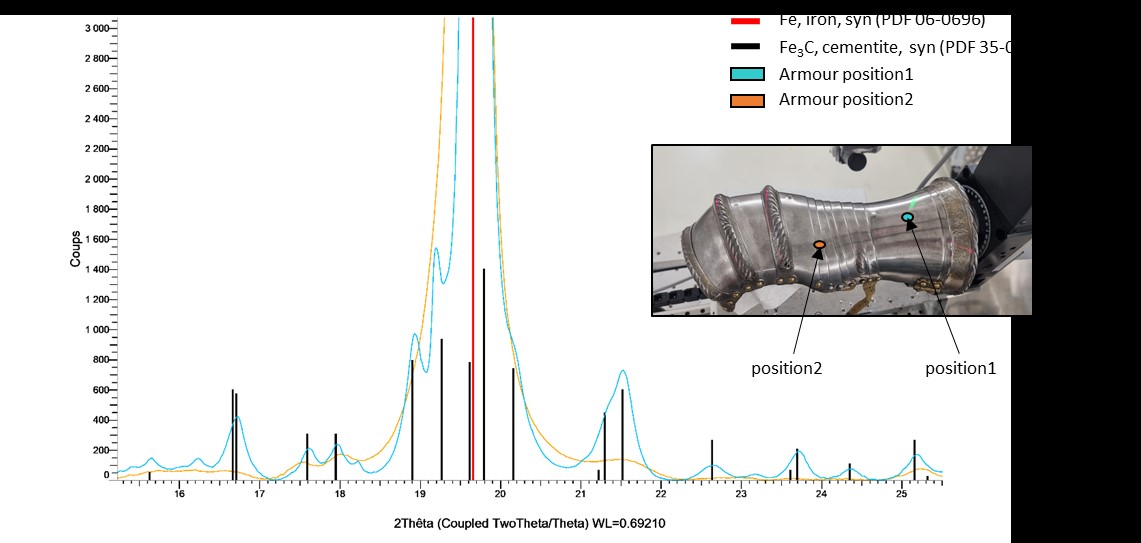

To address this, non-invasive techniques such as X-ray diffraction are well suited to identify the presence of different crystalline structures, characteristic of ferrous alloys, such as ferrite or cementite (Fe3C). For this purpose, X-ray diffraction measurements have been performed on the DIFFABS beamline.

The complex geometry of the pieces of armor required the implementation of a set-up and a methodology adapted to the analysis of this type of object (Figure 2). This methodology was then applied to the exceptional study of a dozen pieces, including a large suit of armor from the Musée des Beaux-Arts in Rennes, all stamped with the -mark of the famous Nuremberg workshop of Valentin Siebenbürger and deposited on this occasion by the Musée de l'Armée, which is responsible for its safekeeping.

The rapid acquisition of diffractograms has made it possible to multiply the analyses on the same object in order to estimate the variability of the alloys used (carbon content, heat treatments...) at the scale of each part. Heterogeneities related to the nature of the metal, revealed by variations in the intensity and shape of the peaks of certain phases (cementite and ferrite), were thus highlighted and raise new questions about the - manufacturing - processes.

The cross-referencing of data collected by X-ray diffraction and other analytical techniques (X-ray fluorescence spectrometry, metallographic and inclusionary analysis of metal samples by optical microscopy, scanning electron microscopy, mass spectrometry coupled with laser ablation... ) but also with historical sources will bring new elements of reflection on unresolved issues, relating to the organization of work in a workshop, the choice of raw materials made by manufacturers to ensure the quality of the finished product according to its use, and the methods of control of it.

This work is part of a research program including the laboratories listed on the right and benefiting from the financial support of the Fondation des Sciences du Patrimoine.