How does wood dry?

The drying of wood follows mechanisms that are still largely unclear. They involve liquid water in the cell cavities known by their Latin name of “lumina” (singular “lumen”) but also water adsorbed in the cell walls. Researchers from the Navier laboratory (CNRS, École des Ponts ParisTech, Université Gustave Eiffel), of the ANATOMIX beamline at SOLEIL and of the Laboratory for Mechanics and Civil Engineering (CNRS, Université de Montpellier) have now demonstrated that the adsorbed water serves as a “bridge” that allows liquid water to leave the lumina and ultimately reach the wood surface where it can evaporate. The study was published in the journal Physical Review Applied.

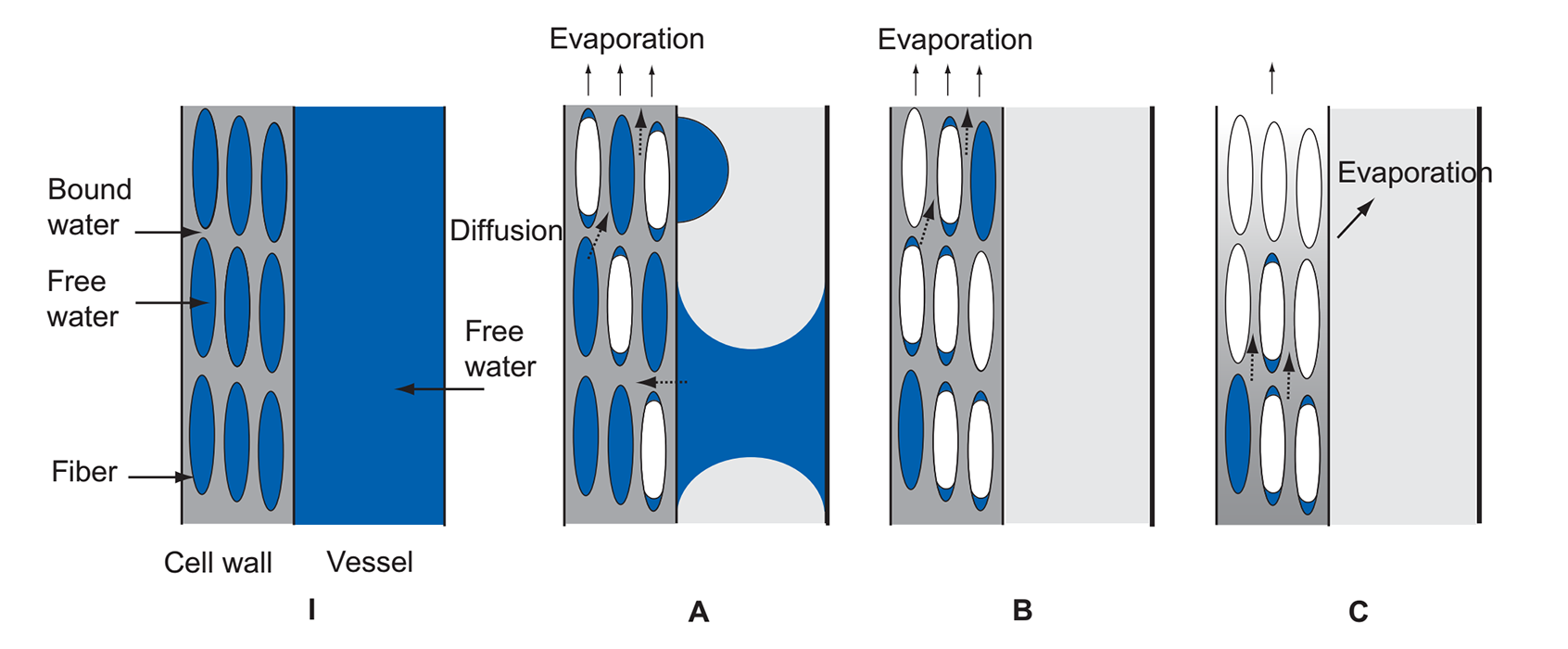

After trees have been cut, the fresh wood, called “green wood”, is usually dried before further use or processing so that its humidity is in equilibrium with the environment of its final use. Drying the wood before processing improves the properties of the final products, reduces size variation and distortion after processing and protects wood from biological attacks. Although wood has been used as a material in construction, tooling, sculpture etc. for thousands of years, the internal mechanisms of its drying are still poorly understood today. It is well known is that green wood contains water essentially in two different forms: “free water”, present in liquid form (e.g., in the fiber and vessel lumina for hardwoods), and “bound water” inside the cell walls, adsorbed to their lignocellulosic constituents.

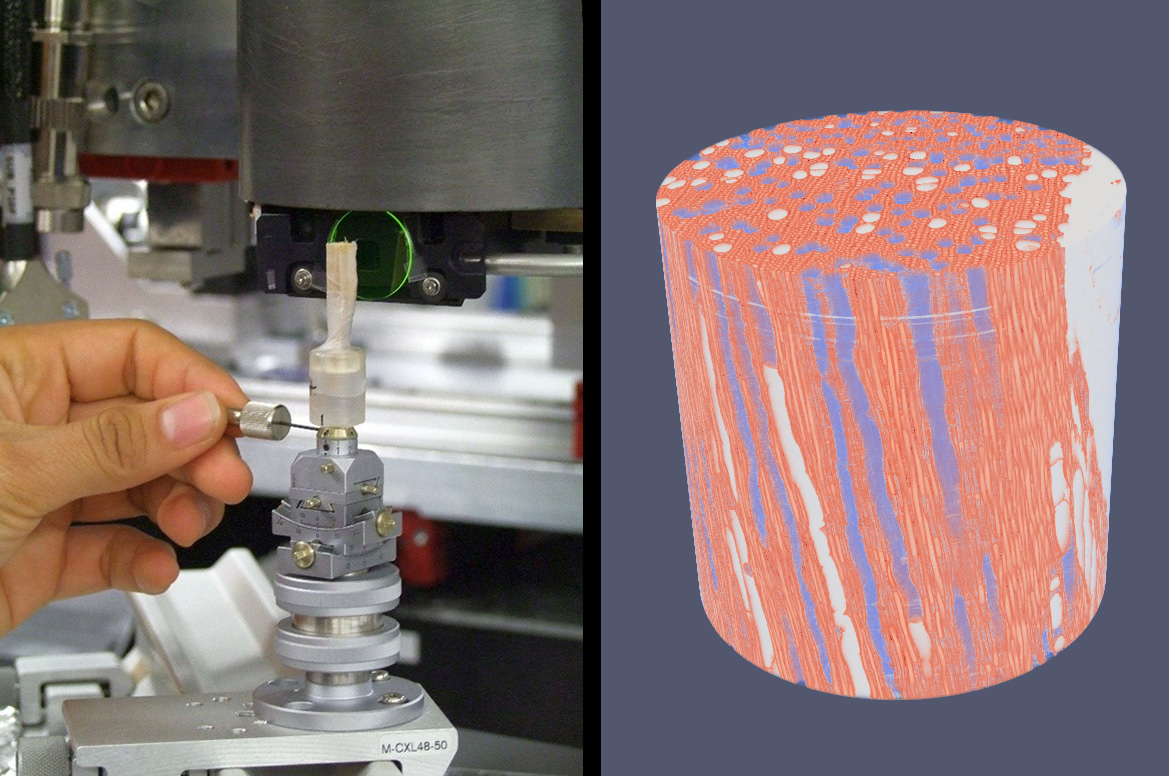

To understand how the free water reaches the wood surface where it can evaporate, a team of scientists from the Navier Laboratory, Champs-sur Marne, led by Sabine Caré and Philippe Coussot, together with researchers from Synchrotron SOLEIL and from the Laboratory for Mechanics and Civil Engineering in Montpellier made extensive measurements on samples of poplar wood taken after the trees had been cut down (Figure 1 a). In addition to weighing the samples while they were drying, to follow the global quantity of water evaporated as a function of time, the team also applied much more sophisticated methods. Thus, nuclear magnetic resonance (NMR) on the Navier premises was used to dynamically follow the decrease of bound and free water in the samples. Moreover, with the initial help of another scientist from Navier Laboratory and frequent user of Synchrotron SOLEIL, Michel Bornert, the team made a series of X-ray phase-contrast microtomography measurements (Figure 1 b) on SOLEIL’s ANATOMIX beamline. Analyzing the movement and morphology of the free water on the micron scale led them to identify the drying mechanisms. These in-situ 3D X-ray imaging experiments of green wood during drying at a voxel resolution of 1.3 µm were made possible by the time resolution and enhanced contrast available in high-resolution microtomography at the ANATOMIX beamline.

Right: Three-dimensional rendering of a synchrotron X-ray microtomography volume image of poplar during drying. Vessels and fibers filled with water are shown in blue, empty ones in white and light orange, and cell walls in dark orange. (Picture: Penvern et al.)

The team found out that the wood dried at a constant rate, which usually means the process is dominated by capillary effects. However, since much of the free water is located in fiber lumina that are not well connected to each other, this can be excluded as the dominant mechanism. Based on their findings, the researchers have established a model according to which free water is adsorbed in the walls of vessels and fibers and is thus transformed into bound water. This bound water then acts as a “bridge” by which water can travel to the wood surface. As it evaporates at the free surface, the remaining free water dissolves into the biomass of the wood and the water drainage process continues (figure 2) until drying is sufficient for technical and industrial applications of the wood.