Frozen sponge cake under the ANATOMIX X-ray microscope

Porous products such as mousses, bread or pastries represent a significant portion of frozen food products; yet few studies have focused on the mechanisms involved at the microscopic scale during their freezing. As part of work for a thesis co-directed by teams from INRAE, Paris-Saclay University, AgroParisTech, Grenoble Alpes University, CNRS and Météo France, these mechanisms have now been studied by X-ray microtomography on the ANATOMIX beamline at SOLEIL. The method developed can be extended to characterise the microstructure of other frozen products.

Control of the cold chain is crucial for the quality of frozen food products from their production to their consumption. Physical modifications that can alter their quality, particularly under the effect of temperature fluctuations, need to be understood. These modifications are essentially linked to the initial microstructure of the products defined by the freezing process during the formation of ice crystals. The microstructure then evolves by recrystallization (growth in size of ice crystals) and sublimation (dehydration on the surface and formation of frost), which occur during storage. While it is now recognised that the microstructure of food products has a strong influence on their physical and textural properties, their taste, and also their stability and therefore their shelf life, the mechanisms that intervene at the microscopic scale are still poorly understood. The majority of studies dealing with the microstructure of frozen foods concern meat and seafood products. A few relate to plant products. Porous products have so far been only little studied although they represent a significant portion of frozen food products. Their high porosity (>50%) makes them more difficult to investigate, especially due to water transfer coupled with heat transfer at the pore–matrix interface (evaporation-condensation phenomenon).

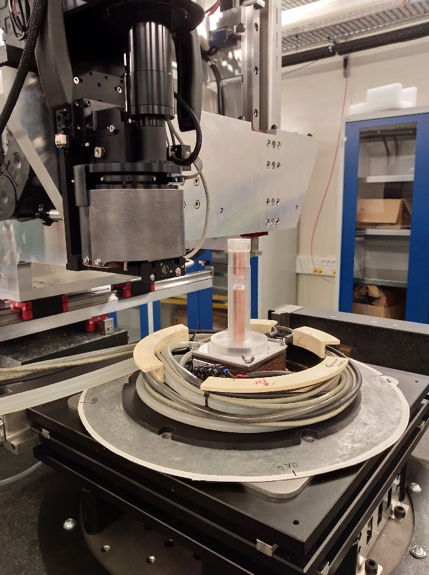

To study the freezing and storage of frozen porous food products, teams from INRAE, Paris-Saclay University, AgroParisTech, Grenoble Alpes University, CNRS and Météo France have joined forces around work for a thesis. A porous model product of simple formulation and controlled manufacturing was developed (sponge-cake model material). For several years, the teams involved have been using X-ray microtomography to visualise and characterise the three-dimensional microstructure of frozen food and non-food products such as snow. They have developed specific cells for maintaining samples in a frozen state during X-ray tomography measurements, but also to vary their temperature and follow the evolution of their structures. The CellStat rig developed within CEN/CNRM for snow is an example (Figure 1).

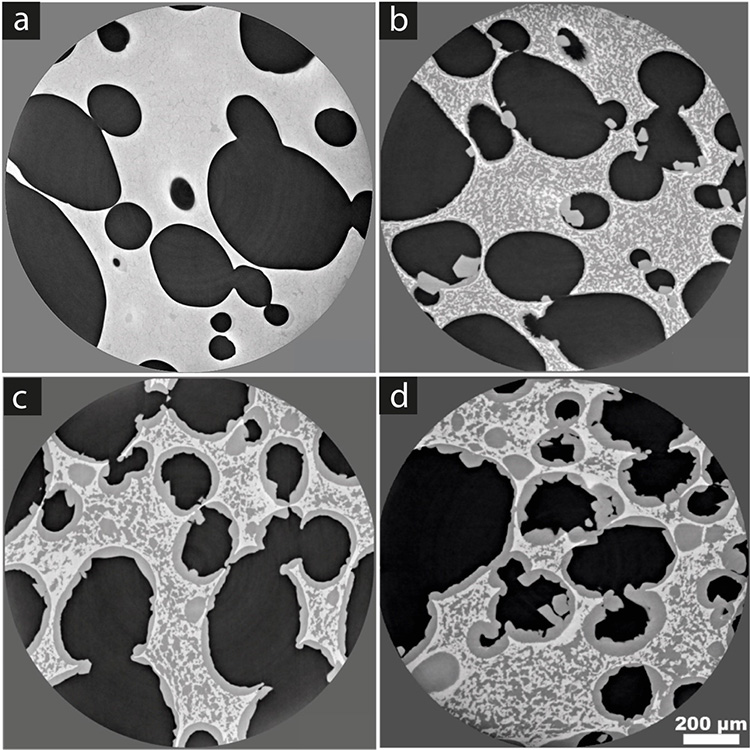

One of the challenges in this work was to obtain 3D images with sufficient contrast within the sponge cake to differentiate pores, ice and matrix with a spatial resolution ranging from the submicron scale to several hundreds of microns and an acceptable temporal resolution. Only X-ray microtomography at the synchrotron can yield such images (Figure 2).

(a) before freezing

(b) after rapid freezing

(c) after slow freezing

(d) after slow freezing and storage for 7 days at -20°C

The ANATOMIX beamline is dedicated to three-dimensional X-ray imaging at these length scales and provides radiographs of high contrast and resolution. The microtomography instrument on the beamline operates in a photon-energy range suitable for imaging centimetre-size low-density and weakly-absorbing samples such as biological and food products. A collaboration with the ANATOMIX beamline team was started; preliminary tests allowed the adaptation of the CellStat rig to the microtomography stage of the beamline and for sponge cake samples.

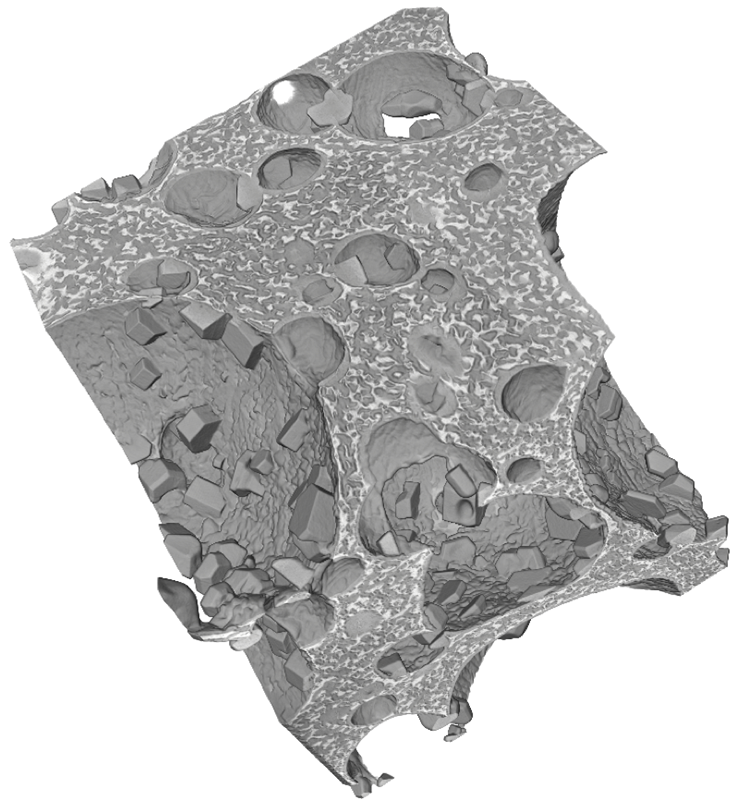

Series of tomography scans on ANATOMIX yielded high-resolution 3D volume images (voxel size 0.65 μm) of more than 50 samples of sponge cake before and after freezing with different storage conditions in the laboratory: slow and rapid freezing, storage for different periods at constant temperature or with calibrated temperature fluctuations.

The images obtained highlighted the microstructure of the sponge cake before (Figure 2a) and after freezing (Figure 2b, 2c and 2d). The pores appear in black on the horizontal sections, the matrix of the sponge cake in very light grey and the ice in darker grey. During rapid freezing (17 °C/min), the ice seemed uniformly distributed within the matrix of the sponge cake (Figure 2b), no ice layer formed at the interface and the water did not seem to have had time to diffuse towards the pores, even if a few isolated crystals appeared. Figure 3 provide a 3D visualization of the shape and the localization of these crystals. During slow freezing (0.3 °C/min), a thick ice layer formed at the matrix/pore interface (Figure 2c); the water contained in the matrix seems to have diffused towards the pores during freezing. During storage of a slow frozen sample at–20 °C for 7 days without temperature fluctuation (Figures 2d), the structure of the sample was slightly modified, the ice layer formed at the pore–matrix interface is thicker and more crystals appeared in the pores. This preliminary analysis suggests that the phenomena at the interface and the microstructure depend on the speed of freezing and the duration of storage. A more detailed analysis will provide a better understanding of the water transport mechanisms involved in the freezing and storage of porous products.

More generally, the methodology developed to make calibrated test samples, maintain them at constant non-ambiant temperature during X-ray tomography measurements and the systematic processing of the images obtained on the ANATOMIX beamline can be extended to microstructural characterisation of other frozen products —food, biological or other— that need to be imaged at low temperatures.