What's inside tree trunks? The WoodSun project provides a 3D answer

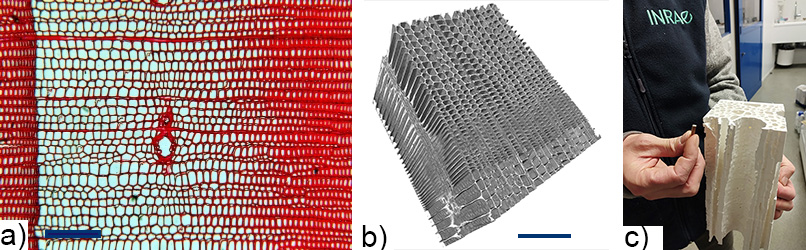

Imagine being able to explore what's hidden inside different types of wood, on a micrometer scale, all without destroying the trees or using a microscope! This is precisely the aim of Eric Badel and his team's WoodSun project, carried out in collaboration with SOLEIL and based on X-ray microtomography implemented on the PSICHE beamline. Like a scanner, this technique enables the reconstruction of 3D images of the interior of analyzed objects. The data obtained on PSICHE are then converted into files that are "readable" by 3D printers, which then reproduce replicas of wood samples at a scale of x 1000 (one micrometer becomes one millimeter), revealing details invisible to the naked eye. A true dive beneath the bark!

The WoodSun project is part of the "Sciences of Wood" GDR (research group), funded by CNRS, INRAE, the French Ministry of Culture and AgroParisTech. This GDR - a structure that fosters exchanges between scientists from the different entities mentioned above - focuses on the characteristics of wood, from biology to engineering, while exploring the links between structures and properties. It coordinates educational initiatives, shares resources and collaborates with the scientific community and industry professionals.

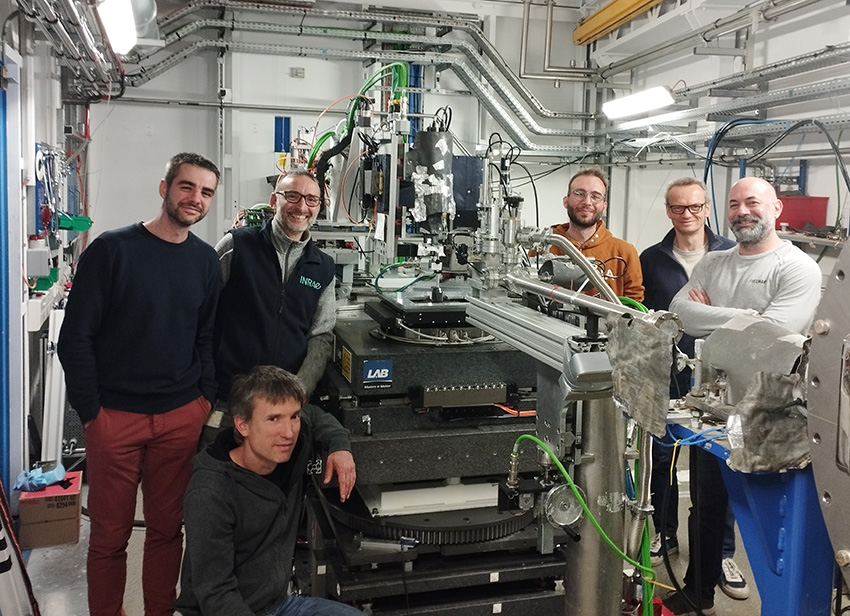

As part of this GDR, an inter-laboratory team (see figure 1) set itself a challenge: to produce a new teaching tool, enabling everyone to appreciate the diversity of wood microstructures without a microscope! With this in mind, the scientists asked SOLEIL for help.

There is a huge diversity of wood species, each with its own special properties, be they physical, mechanical, olfactory or chemical. These properties are defined, in part, by very different anatomical structures. For example, the functioning of a tree depends largely on its vascular system, which transports water from the roots to the leaves via internal channels. Mechanically, wood also plays a crucial role in providing structural support for the tree, requiring a robust structure to withstand its weight and environmental stresses such as wind. In addition, wood serves as a storage area for various substances produced by the tree, such as carbon reserves (sugars) that can be mobilized when needed to resist cold or meet other requirements. These three main functions - hydraulic conduction, mechanical support and storage - are essential to the tree's longevity and are characterized by very precise and specific cellular structures that vary between species and their environmental growth conditions. Knowing, identifying and understanding these structures enables us to make the best possible use of each species of wood (in construction, the food industry, etc.).

Eric Badel: "We know a great deal about some of these structures, such as oak and beech, but less about the diversity that exists on a planetary scale. In order to catalogue this diversity of woods, scientists have always brought back samples to store them, archive them and create what is called a xylotheque."

These xylotheques can be used to produce atlases and books listing cross-sections and images of wood structure, with the aim of identifying and recognizing woods and making this information accessible to as many people as possible.

Eric Badel: "These xylotheques are an important part of our heritage and have been gathering knowledge on all the wood species in the world for several centuries. For this project, we are more interested in the woods currently available on the planet."

Very few people have access to xylotheques and atlases, and what's more, if you want to look at the differences between wood species, you have to use a microscope. Ten years ago, by combining laboratory X-ray microtomography, image analysis and 3D printing tools, Eric Badel created the first accurate 3D model of an oak wood microscope structure, which he has used as a teaching tool for students and at public events. “The model has proved very useful, and teachers at both secondary and higher education levels are very keen to use it!”

The aim of the project is to make the microscopic structure of different types of wood accessible and visible to all. But it also has a conservation objective, as some xylotheques are almost 100 years old and fragile: “this project therefore also has a vocation to safeguard this heritage in digital form”.

To carry out the project, Eric and the team from the various GDR “Sciences of Wood” laboratories turned to SOLEIL Board, where they used X-ray microtomography. This technique, like a scanner, enables 3D visualization of the internal structure under study at sub-micron resolution. Once the tomography has been carried out, the volume image obtained is transformed into an object using a 3D printer - a replica of the wood sample analyzed, enlarged as required.

3D exploration at SOLEIL: revealing wood structures

It was on PSICHE, SOLEIL's high-resolution high-flux X-ray microtomography beamline, that Eric and his team produced the microtomography images, with the help of beamline scientist Andrew King.

Eric Badel: “We can carry out microtomography in our laboratories, but only on a few samples. Here, the speed of acquisition means that we can produce around 200 high-quality scans in only 48 hours. And we do this at different spatial resolutions to visualize anatomical elements down to submicron scale. On our laboratory equipment, the image quality obtained is much poorer, and it would then take days of image-processing work to clean up each volume; whereas on scans taken on PSICHE, a few hours would suffice. Without the synchrotron, the project wouldn't have been possible on this scale.”

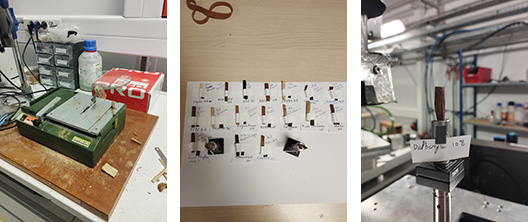

In practical terms, microtomography is carried out on small wooden bars cut from samples taken from two large xylotheques (AgroParisTech in Nancy and CIRAD in Montpellier) and placed on a sample holder. Image acquisition takes just a few minutes. The next step is to transform these volumetric images into data that can be used by a 3D printer. In all, over a hundred temperate and tropical tree species have been scanned, representing over 20 terabits of data in the end! And it will take almost two years to process all the files and make them available to everyone.

In the spirit of Open Science, the files processed in the GDR Sciences of Wood laboratories, and in particular the PHENOBOIS Clermont-Ferrand platform, will gradually be made available on the Internet as open source (accessible to the public). The first files are available on the GDR website https://eng-gdr-sciences-du-bois.hub.inrae.fr/resources/wood-3d-printing

Outlook: an innovative database for comparative studies

Ultimately, the project aims to create a database listing the name, cross-section, tomography image and 3D printer file of each essence. This database will enable students and scientists to discover and study the structures of different wood species and compare their physical and mechanical properties.

a) 2D image obtained by optical microscopy (x20) on a safranin-stained section of a spruce sample, showing the network of cells used for water conduction and mechanical support of the tree (scale bar: 200µm).

b) 3D image also obtained on a spruce section by X-ray microtomography on PSICHE, with a resolution of 0. 63µm/pixel; the cell walls are clearly visible (scale bar: 200µm).

c) 3D model of the internal structure of an oak sample (held by Eric Badel, left), obtained by 3D printing from PSICHE X-ray microtomography measurements.

Eric Badel: “When you create a database, you have a few ideas of what it will be used for, but you don't know exactly what its future uses will be. There are bound to be communities who will want to see particular things about these objects that we haven't thought of yet! That's why, in addition to the printable files, we're thinking about how to make the raw images scanned on PSICHE available in an institutional data warehouse. That's the whole spirit of the Open Science project we're involved in.”