Resumption of industrial experiments at SOLEIL

At SOLEIL, initial experiments, notably in the case of industrial experiments, have resumed in compliance with the current regulations for the safety of all.

For several years now, SOLEIL has offered a number of different services to companies, such as the "mail-in service" available since 2008: the sample is sent in by the company, then SOLEIL collects the data and delivers it back to the company; or the "remote-access" service: remote-controlled access available since 2017 to companies on PROXIMA 1 (PX1) and PROXIMA 2A (PX2-A) beamlines. Since the implementation of these services, more than 250 industrial experiments have already been carried out by "mail-in-service" and more than 40 by "remote-access".

These cutting-edge services make all the more sense in this period, when we need to maintain physical distancing rules, while responding to the urgent needs of businesses to maintain their activity: this is a priority for SOLEIL, whose mission is to support businesses, in particular start-ups and SMEs.

As a result, some thirty industrial experiments involving both biology and materials and lasting from 2 up to 8 hours, were scheduled in June.

Biology:

Spotlight on the biocrystallography experiments that were scheduled via "remote-access" and "mail-in service" as soon as SOLEIL reopened.

Interview with Tatiana Isabet, Industrial applications engineer in biocrystallography.

Tatiana, could you explain how a "remote-access" session with a client works?

"As in the case of a "mail-in service" experiment (fully sub-contracted to SOLEIL), after receiving the dewars (containers containing the crystals) sent by our customers to the SOLEIL warehouse, they are dispatched to the (PX1 or PX2-A) beamline at 2pm. Once I receive them, I fill them with liquid nitrogen.

To carry out the experiment, I position the "pucks" (containing 16 crystals each) in the robot dewar filled with liquid nitrogen, the beamline robotic arm collects the samples there. The collection is controlled from the beamline control cabin, via "MXCuBE" software.

In the case of the "mail-in service", I carry out the collection myself according to the instructions previously sent to me by our clients. If they wish, the company can remotely monitor the progress of the collection that I carry out for them, via the "ISPyB" application. However, not all do so and prefer to take advantage of this complete outsourcing to concentrate on other related activities. The experimental data are then forwarded to them.

In the case of "remote-access", it is the companies themselves, connected via the "NoMachine" software to SOLEIL, who control "MXCuBE" remotely and pilot the data collection from their own premises. In this way, they are in control of the collection, but I am available at any time as a dedicated local contact (1), to assist with any questions or technical issues, via a dedicated chat line on "MXCuBE", or if necessary, via other means (WhatsApp, SMS, phone call...), often at start-up if they haven't conducted a "remote-access" session in a long time, to help them get used to the tools. The companies retrieve their data directly from the Ruche (2) by connecting to the "mukade" machine, which can be accessed externally to SOLEIL, or wait for the return of their dewar containing the hard disk with their data. At the end of the experiment, I put the pucks back in the corresponding dewars. They are then sent back to the SOLEIL warehouse for the return trip, which I organise (from the contact information forwarded by each company).

Responsiveness, flexibility, reliability

The "remote-access" service, is much appreciated by companies, who can then easily conduct the urgent collection themselves without having to travel, for small quantities of crystals for example, when we have availability between two experiments, or a slot is freed up at the last minute. This avoids the need to organise travel, especially for those coming from far away for a short session. This service can be used occasionally or more regularly if the companies wish. The fact that I am on site, available at any time, ensures that the remote-access session runs efficiently and that time is well optimised. It is the ease of collecting your data from home with a support service if needed."

----------------------------

(1) Beamline scientist, the point of reference for a given user experience, available to welcome and guide, or even troubleshoot, users in the event of an on site or remote issue.

(2) Experimental data storage platform, internal at SOLEIL

Fabrice Ciesielski from the Novalix company

Interview: Fabrice, can you tell us about your links with SOLEIL?

"Initially, we were an ESRF client (from 2003 to 2010 via Alix) and started using SOLEIL in 2011 during an upgrade of the Grenoble synchrotron, when SOLEIL started to offer its services to companies. We were a little worried at first about the flow aspects because SOLEIL was not yet automated, but we were rapidly convinced by the data quality obtained and the expertise of the on-site teams, who were readily available to assist us and debug problems during our collections. The service quality/price ratio proved instantly beneficial to a small structure such as ours, which led us to continue with our access to SOLEIL. Since 2011, the biocrystallography beamlines have been automated with robot samplers. The outstanding human relations we have forged with the SOLEIL experts is a scientific advantage for us. It is an all round win-win exchange that we wish to maintain".

The lockdown: what were or are the impacts on your activities?

"Before the lockdown was announced, and because we chose to maintain our activities, we moved quickly and implemented physical distancing measures. We encouraged the use of remote working where possible, and adapted working hours for employees who could not work remotely. This is the case, for example, for colleagues working on the experimental part, who work shifts (morning and afternoon shifts) to limit the number of people in our laboratories. As a result, we were able to continue our activities even though the work volume has nevertheless decreased.

At the beginning of lockdown, following the general shutdown of the synchrotrons and in particular the SOLEIL synchrotron, we were concerned that we would not be able to meet our clients demands. But ultimately our clients were also impacted by the lockdown and were no longer able to provide us with their compounds to co-crystallize. Consequently, certain "cristallo" projects were put on hold.

On the other hand, other projects in development could continue, notably on the biochemical aspects".

How have you experienced "remote-access"?

"When we visited SOLEIL, we often spoke to Tatiana about the remote-access possibilities that we needed to test but had never found the time to do so. The lockdown constraints forced us to take the plunge, and the test on June 2, before our 8-hour remote-access session on June 4, was conclusive. We encountered the same conditions as we did on site, with no waiting times during data acquisition.

We are considering using this service - which is new to us - in the future as an alternative, for example, for short sessions or when the organisation of a mission from Illkirch (67) to Saclay is inconvenient.

However, we would like to continue travelling from Alsace, because we value the discussions we have with Tatiana and the teams on the PX1 and PX2-A beamlines. These casual discussions during the experiments are rewarding and valuable to us and our activities."

What are your fields of activities and services to your customers?

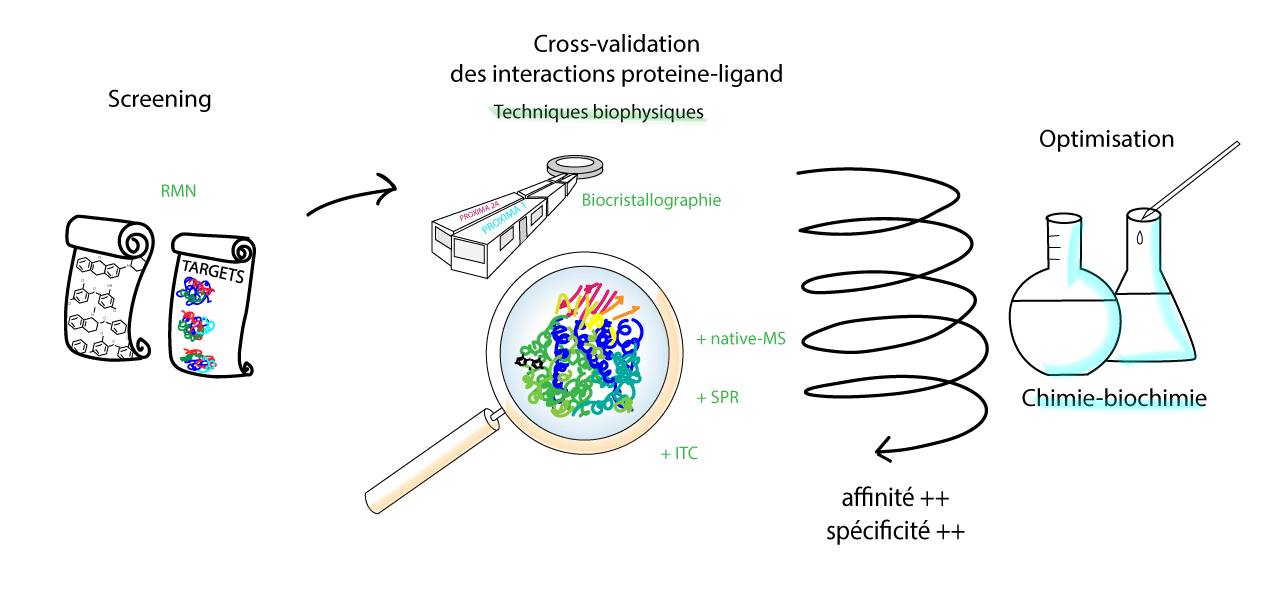

"For the pharmaceutical sector (which represents 80 to 90% of Novalix's activities), we are involved at an early stage in the search for new drugs, by identifying the first potential candidate molecules. For this, we first screen by NMR (nuclear magnetic resonance) a large number of molecules on therapeutic target proteins, before cross-checking(3) the hits(4) by other biophysical techniques (native-MS(5), SPR(6), ITC(7), biocrystallography...). This is why we come to the synchrotron, to conduct biocrystallography on protein-ligand crystals that we produce at Novalix (a platform for the production, purification and crystallization of target proteins), in order to study the interaction of chemical molecules with their target protein. The 3D structure of the complex provides us with insight into the binding mode at the atomic level, therefore guiding the synthesis of new molecules by iterative cycles between the chemistry and biochemistry teams and us, crystallography, thereby optimising the molecules of interest. We then hand over to our clients who handle the rest of the process (ADME-TOX trials(8), pre-clinical, clinical development, marketing authorization, etc.).

For other projects, we are solely "asked" for our expertise in biocrystallography, in this case, we determine the 3D structure of protein complexes with our client's proprietary molecules.

----------------------------------

(3) Confirm by cross-checking using another technique

(4) Positive screening responses

(5) Native mass spectrometry of biomolecule interaction, i.e. non-modified, also referred to as "supramolecular" spectrometry. This technique makes it possible to analyse whole macromolecules and complexes of several molecules.

(6) Surface Plasmon Resonance

(7) Isothermal Titration Calorimetry

(8) A drug's activity depends on 5 criteria: absorption, distribution, metabolism, excretion (corresponding to the successive stages a drug goes through in an organism) and toxicity. This type of trial is designed to assess these criteria in order to select molecules suitable as drug candidates.

How is Novalix structured and what are your other application sectors?

"Among the 120 people at Novalix, 1/3 work in the biochemistry/biology section and 2/3 in the chemistry section.

50% of our colleagues work on site in Illkirch (67) and 50% are "in-sourced", i.e. they are seconded on site to our clients or partners, for example 7 people from Novalix work at the SERVIER Structural Biology Laboratory at SOLEIL (LBS3), for our client SERVIER.

As previously mentioned, the majority of our activities involve the pharmaceutical sector, but we also have applications in the cosmetics, agri-chemicals and fine chemicals sectors, where the same methods are used to optimise the functioning of certain molecular systems. This is the case for example in biocatalysis, with mutant proteins that promote the transformation of precursors for the synthesis of biofuels and in which we are investigating the impact of the modifications to these proteins and their dynamics in order to improve their enzymatic activity".

Fabrice, can you tell us about the fragment libraries used in drug design?

"Since its beginnings, Novalix has proposed a fragment library to identify candidate molecules either by NMR (fast and robust) or by other more informative biophysical characterization techniques (native mass spectrometry, crystallography, surface plasmon resonance (SPR)). Moreover, since 2018, we have entered into a partnership with the Pierre Fabre Laboratory to gain access to their (Natural Fragment Library) plant extracts, which effectively completes our range of tools in our biophysics platform. The diversity and complementarity of the biophysical techniques that we propose is essential to guide chemistry from small chemical molecules (low molecular weight and low affinity) and synthesize more complex molecules with better affinity and specificity for the target protein."

What about materials?

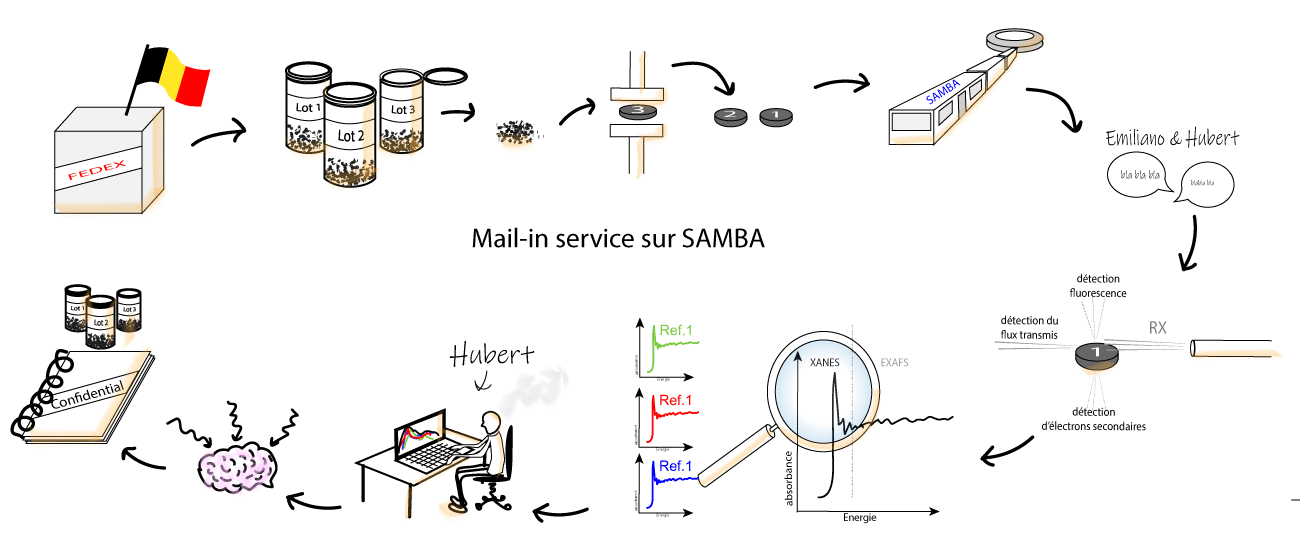

The first industrial experiment on materials took place on May 28 on SAMBA via the "Mail-in" service.

Our colleagues, Emiliano and Hubert, began setting up the beamline on Thursday morning (in this case for measurements at the Cobalt edge) for a new SOLEIL client from Belgium. And despite a slight delay in delivery, the samples finally arrived on time, on Thursday at noon.

Hubert was able to quickly condition the samples at the Chemistry Laboratory (powders from 3 lots, compacted into pellets) while Emiliano completed SAMBA's adjustments.

Luckily, the cobalt concentration in these three batches was sufficient and the measurements on the 3 pellet samples could be carried out by our colleagues relatively quickly on Thursday afternoon.

The obtained spectra could now be processed and compared (fitting(9), linear combinations...) to the spectra obtained from reference samples (suspected chemical forms of cobalt in our client's mixture) that Emiliano was able to measure the day before under experimental conditions similar to those of the 3 batches measured on Thursday 28, May.

Once the experiment was completed, Hubert was able to leave with the data collected in order to process, analyse and interpret them according to the company's request and in accordance with SOLEIL's contractual commitments. The analysis will make it possible to identify the chemical forms of Cobalt present in each mixture. The analysis report was delivered to our customer at the beginning of the next week.

We would like to thank our colleagues for their reactivity, synergy and investment in SOLEIL's commitment to companies.

----------------

(9) Research to match experimental spectra with reference spectra

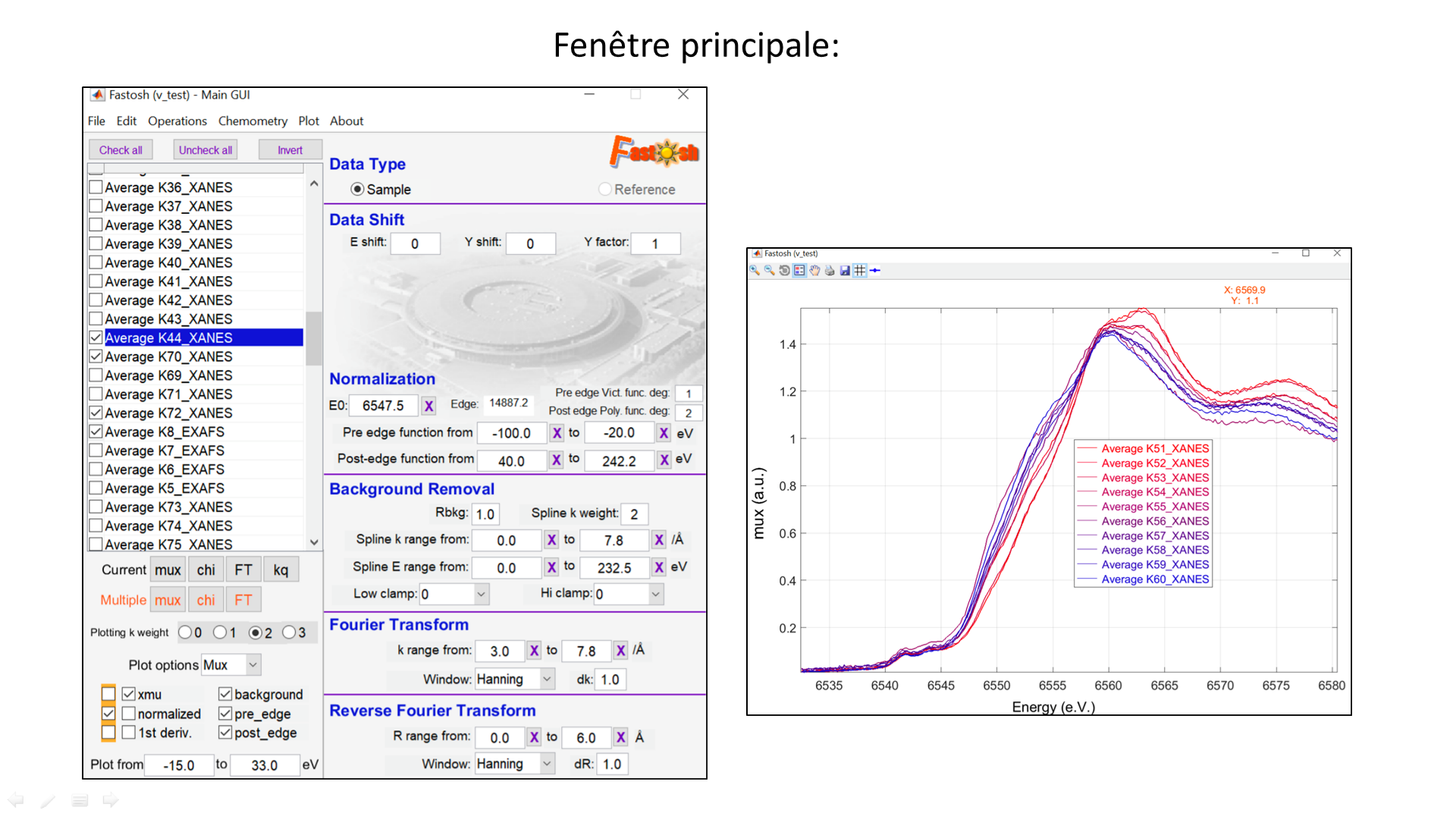

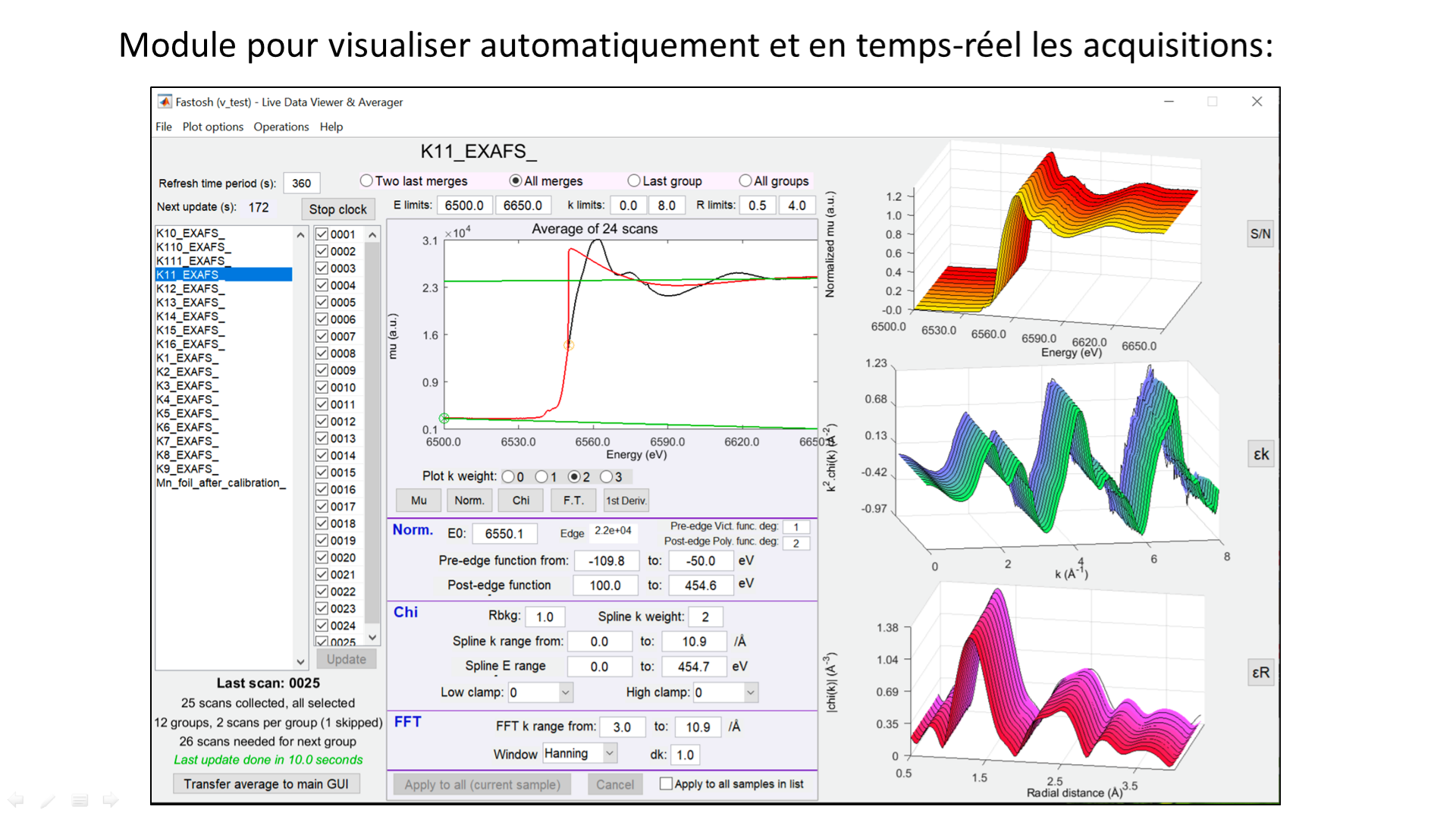

"Fastosh" as quick and easy

To meet the analysis needs of Companies, Hubert used a particularly useful programme developed by Gautier for use with SAMBA, but not only.

This standalone, freely available programme, called Fastosh, can quickly process (normalizing spectra, background noise subtraction, removal of artefacts among others...) raw X-ray absorption spectroscopy data generated in ASCII format, whether they are obtained step-by-step or in-situ in high throughput (in continuous acquisition mode for example).

The motivation behind Fastosh was to provide tools to:

- exploit the complete data of SAMBA's multi-pixel fluorescence detectors;

- automatically view results in real time to help users determine when enough data has been collected and when the acquisition can be stopped;

- better identify the nature of chemical forms present in complex mixtures, thanks to chemometric tools included in Fastosh;

- easily create figures to optimise the exploitation of results in articles, SOLEIL's experimental reports, or analysis reports for industrial applications, among others.

The test version of this programme has been available since the beginning of 2020 and is accessible on the beamline via a user-friendly interface inspired by an environment well known to the XAS community (Athena). It allows users to process data online and in real time, and to monitor the progress of acquisitions, in addition to offering other particularly useful functionalities for geochemical and environmental applications.

To find out more: https://goldschmidtabstracts.info/2018/1402.pdf