Caffeine in cosmetics – optimizing its release into the body by means of "MOFs”

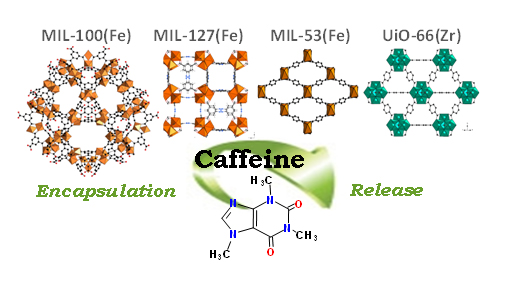

Hybrid metal-organic frameworks or MOFs are very promising candidates for applications in strategic areas such as catalysis, separation or, more recently, biomedicine. A group from Institut Lavoisier de Versailles, pioneer in the MOF biomedical field, has studied, notably on the CRISTAL beamline, the encapsulation and release of caffeine, which is of great interest to the cosmetics industry due to its lipolytic action.

MOFs or (metal-organic-frameworks) typically consist of a regular assembly of inorganic entities (clusters, chains, planes…) and organic ligands combining polycomplexing functions (carboxylates, phosphonates…).[i]

These crystalline solids possess a network of cavities and channels with an important porosity (pore diameter F = 3 - 60 Å; specific surface area SBET = 100-6000 m2.g-1; total pore volume V = 0.2-4.0 cm3g-1). The versatility of their structures (wide variety of porosity/connectivity, topology, etc.) and their chemical compositions make MOFs very promising candidates for applications in strategic areas such as catalysis, separation[i,ii] or, more recently, biomedicine[iii] . In particular, their high and regular porosity, as well as the presence of an amphiphilic environment (having both hydrophilic and hydrophobic parts, cation and organic ligand), well-adapted to the adsorption of drugs with different composition and structure, have led to remarkable encapsulation capabilities and their progressive release under physiological conditions[iv,v] . A thorough microscopic understanding of both the encapsulation and release of the active ingredient from MOF-type carriers is crucial for a good control of these processes. This has motivated the recent studies of the group of Institut Lavoisier, pioneer in this field, which are focused on streamlining the encapsulation of therapeutic molecules in a series of porous MOFs.[vi]

In this context, a systematic study of the main factors governing the encapsulation of active ingredients and their release kinetics from MOFs with various topologies and chemical compositions was performed by combining experimental techniques with numerical simulations. The caffeine molecule exhibiting a remarkable lipolytic action very interesting for the cosmetics field, was selected. Indeed, the current lack of effective caffeine formulations on the market is mainly due to its strong tendency to crystallize, which leads to low capacities (<5% by weight) and uncontrolled releases. [vii]

MOFs have proved to be very promising candidates to overcome this technological barrier in the cosmetics industry (associated publication). In particular, the exceptional encapsulation rate of 50% by weight was achieved using biocompatible MOFs such as the mesoporous iron(III) trimesate MIL-100(Fe). In addition, the structure of flexible MOFs containing caffeine has been analyzed through a combination of high resolution X-ray powder diffraction data on the CRISTAL beamline, and numerical simulations (density functional theory) to better understand the conformation of caffeine and its interactions with the atoms forming the pores.

Furthermore, the release of caffeine strongly depends on the nature of the medium: under serum conditions (phosphate buffer pH=7.4, 37°C), caffeine is rapidly released after degradation of the MOF, while in a simulated skin physiological medium (water pH 6.3, 37°C), caffeine is progressively delivered, as a consequence of the degree of confinement and MOF-drug interactions. Thus, considering a typical cosmetic administration ranging between 8 and 24 h, the most promising porous MOFs for the topical administration of caffeine are the mesoporous iron(III) trimesate MIL-100(Fe) and the microporous zirconium(IV) terephthalate UiO-66(Zr), which combine record caffeine encapsulation rates and progressive release over 24 hours.

[i] Férey G., Chem. Soc. Rev., 2008, 37, 191; Chem. Soc. Rev, 2009, 38, 1201; Chem. Rev., 2012, 112, 673.

[ii] Acc. Chem. Res, 2005, 215; J. Solid State Chem., 2005, 2409; Férey G. et al., Chem. Soc. Rev., 2011, 40, 550.

3 Horcajada P. et al., Chem. Rev., 2012, 112, 1232; Della Rocca J. et al., Acc. Chem. Res., 2011, 44, 957;. Imaz I. et al., Chem. Comm., 2011, 47, 7287.

4 Horcajada P. et al., Angew. Chem. Int. Ed., 2006, 118, 6120.

5 Horcajada, P. et al., Nature Mater. 2010, 9, 172.

6 Gaudin C. et al., Micropor. Mesopor. Mater., 2012, 157, 124 ; Cunha D. et al., J. Mater. Chem. B, 2013, 1(8), 1101.

7 Touitou E., Junginger H. E., Weiner N. D., Nagai T., and Mezei M., J. Pharm. Sci., 1994, 83, 1189.