W164: one insertion device

for two purposes

An out-vacuum wiggler, W164, was

designed, built and installed on the

SOLEIL storage ring with the double

objective to produce high energy photons

for the PUMA beamline (10 keV to 70 keV)

and to be used as a modulator for the

FEMTOSLICING project [1]. The insertion

device requires simultaneously reaching

high critical energy of photons (above 10

keV) and low resonant energy (1.55 eV).

The wiggler is composed of 20 periods

of 164.4 mm made of NdFeB magnets and

Vanadium Permendur poles. The maximum

total field reaches 1.85 T at the minimum

gap and 1.66 T at the FEMTOSLICING

operation gap. The size of the poles,

the carriage and the girders were optimized

to minimize the deformation resulting

from the magnetic forces (8 tons at

minimum gap).

The SOLEIL FEMTOSLICING [2] is a multi–

user project focused on the production of

ultra-short photon pulses (~100 fs). It is

based on the exchange of energy resulting

from the interaction inside a wiggler

(“modulator”) of electron bunches and

an external short pulse laser. The wiggler

resonant wavelength matches the 800

nm laser wavelength (in fact the energy

exchange is optimum when the wiggler

operates at 780 nm). The other specificity

of the SOLEIL modulator is that it is also

used as a high energy photon source (10

keV to 70 keV) for the PUMA beamline [3].

The construction of W164 gathers thus

two goals. The first is to reach low photon

energy which is not the predilection

spectral range of medium/high energy

storage rings such as SOLEIL. The second

is to operate the modulator at high critical

energy. Both constraints require building a

wiggler with high field and large period.

Magnetic design

The magnetic system is composed of

20 periods of 164.4 mm generating a

maximum field of 1.85 T at a minimum

gap of 14.5 mm. Each period consists of

NdFeB permanent magnets and Vanadium

Permendur poles assembled on aluminum

holders and mounted on two aluminum

beams (Fig.

➊

). The magnetic field is

changed by moving the gap between the

beams from 14.5 mm to 240. Particular

care has been taken in the design of the

carriage to avoid excessive deformations

which result from high magnetic forces

between magnet arrays (up to 8 tons).

Thanks to the stiffness of the girders (300

mm), the rigidity of the frame and the

small transverse size of the poles (50 mm),

their planarity and parallelism remain

within 0.1 mm under load.

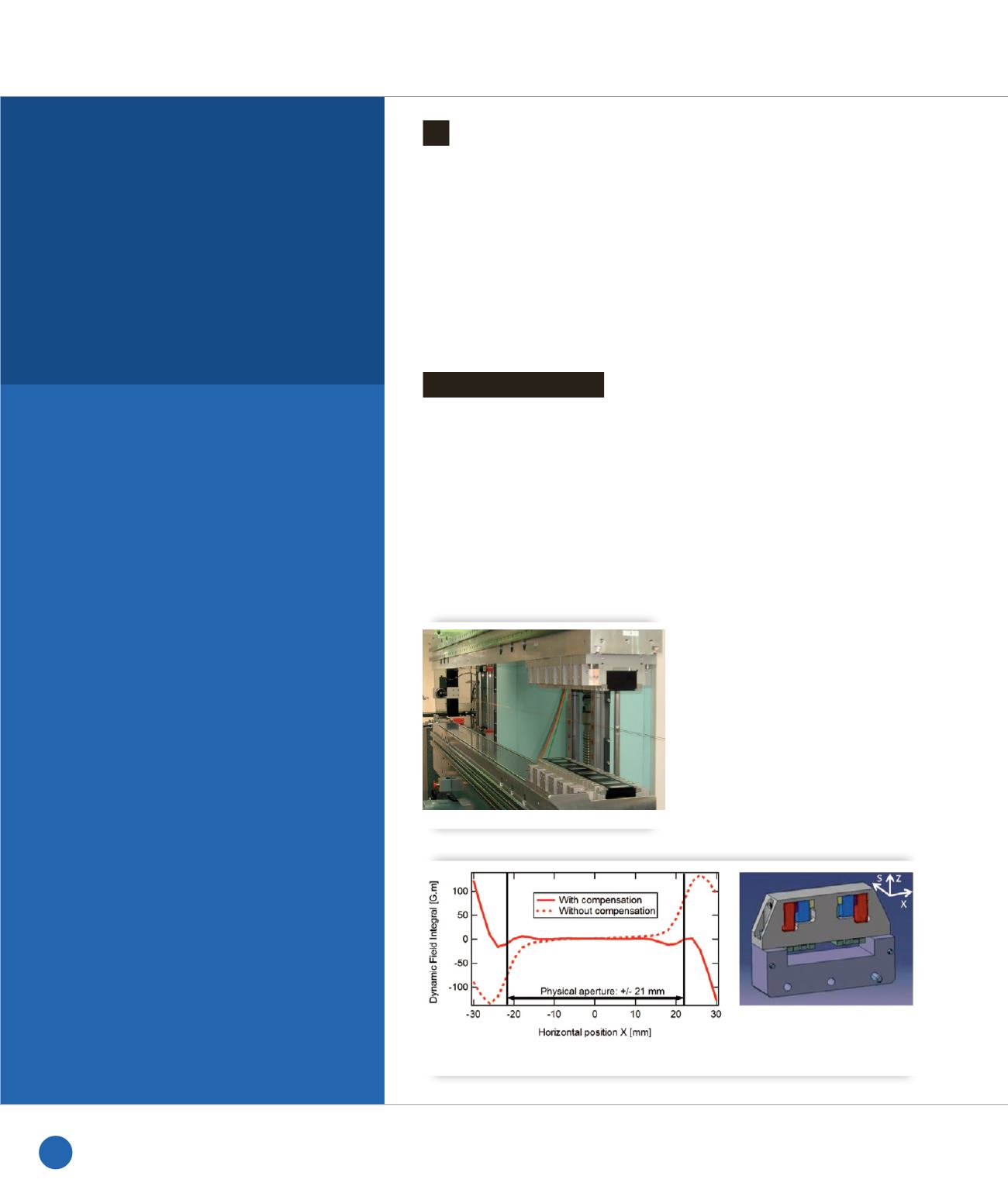

However, the small transverse size of the

poles impacts strongly the transverse

homogeneity of the magnetic field and

generates an off-axis strong field integral

(“Dynamic field integral”) [4] which could

be responsible for nasty effects on the

beam dynamics.

Compensation system

Four dedicated compensation systems

were designed and built at SOLEIL to

reduce the off-axis dynamic field integral

(Fig.

➋

, left). Each of them is composed

of four vertically polarized permanent

magnets mounted in an aluminum box

(Fig.

➋

, right).

Description of W164

➊

W164 during assembling.

➋

Calculated reduction of the dynamic field integral (Left) resulting from the effect of the compensation system

(Right) at minimum gap (14.5 mm).

SOURCES AND ACCELERATORS DIVISION

138

SOLEIL

HIGHLIGHTS

2013